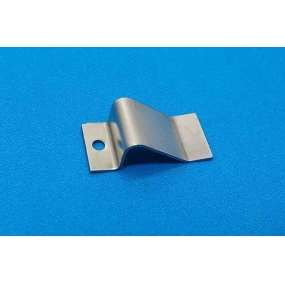

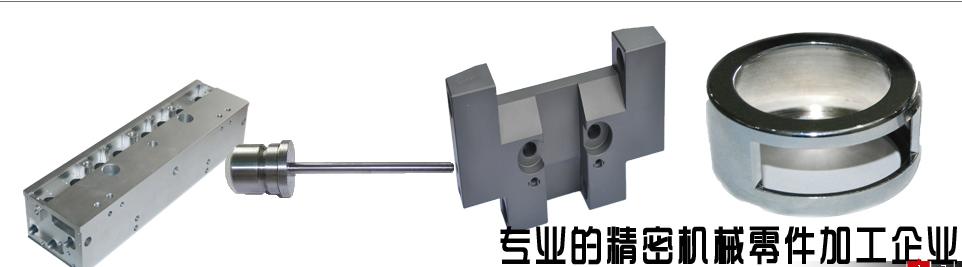

Shenzhen precision parts processing and manufacturing takes high-precision mechanical parts as the processing object. Using systematic and integrated theory and technology, the organic combination and optimization of feeding, processing, testing, handling, etc. are realized according to the structure and requirements of the processed workpiece, and the production of parts is completed under precise processing conditions. Its purpose is to realize the concept of "small machine tool processing small parts", which is a manufacturing method and technology different from ordinary mechanical parts. It will become the most effective processing method for processing high-precision parts of non-silicon materials (such as metals, ceramics, etc.). It can fundamentally solve the problems existing in the processing method of precision instrument parts. It has high precision, low energy consumption, flexible production, high efficiency and excellent. Reducing the size of the entire manufacturing system and precision parts can not only save energy, but also save manufacturing space and resources, in line with energy-saving and environmentally friendly production models. It is one of the development directions of green manufacturing.

With the development of aerospace, national defense industry, microelectronics industry, modern medicine and bioengineering technology, the demand for precision/ultra-precision mechanical parts (feature sizes from micron to millimeter) is becoming increasingly urgent. The specialization of its structure and shape, the diversity of parts materials, and the high precision of size and surface quality have become the significant characteristics of high-precision mechanical parts and their micro-devices and equipment, and the requirements for use functions, material characteristics, structural shapes, and reliability are also increasing.

With the development of aerospace, national defense industry, microelectronics industry, modern medicine and bioengineering technology, the demand for precision/ultra-precision mechanical parts (feature sizes from micron to millimeter) is becoming increasingly urgent. The specialization of its structure and shape, the diversity of parts materials, and the high precision of size and surface quality have become the significant characteristics of high-precision mechanical parts and their micro-devices and equipment, and the requirements for use functions, material characteristics, structural shapes, and reliability are also increasing.

At present, the main precision machinery manufacturers exist in Western developed countries and some developing countries and regions with higher economic development levels (such as Singapore, etc.). The customer base also mainly exists in these regions.

High-precision components are used in testing equipment in all walks of life - scientific instruments, which are mainly used in the instrumentation and instrumentation industry in scientific instruments in China.

Compared with ordinary machinery manufacturing, precision machinery manufacturing has high technical content (design and production), excellent processing equipment, high added value, and sales are mostly differentiated in small batches

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque