Product design is diverse, and texture is one of the factors that affect the appearance of a product. Different textures can bring different styles and feelings. Let‘s talk about laser engraving technology.

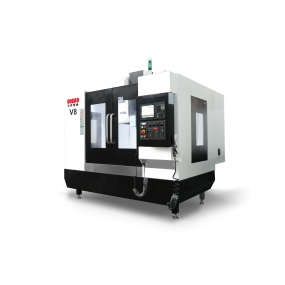

Based on numerical control technology, laser is the medium for Sheet Metal Processing. Metal materials are instantly melted and vaporized under laser irradiation, so as to achieve the purpose of processing. Through the laser engraving machine using laser engraving technology, vectorized graphics can be easily "printed" on the substrate of all Beijing sheet metal processing. The advantages of this technology are:

① Precision: The thinnest line width on the surface of the material can reach 0.015mm, and it is non-contact processing, which will not cause product deformation.

② High efficiency: you can get the actual product of the new product in the shortest time, and you only need to change the vector file for multi-variety and small batches;

③ Special processing: to meet special sheet metal processing needs, it can process inner surfaces or inclined surfaces;

④ Environmental protection and energy saving: no pollution, no harmful substances, higher than export environmental protection requirements.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque