EMAR shares what preparations need to be made in the early stage of production for precision machining?

The production process of precision machining is a complex and delicate process, and the following is a detailed analysis of its main steps:

First, design and planning

First, design and planning

According to the function and requirements of the part, the detailed design is carried out to determine the key parameters such as the size, shape, and tolerance of the part.

Plan the processing route, including selecting the processing method, determining the processing sequence, and arranging the heat treatment process.

Second, material selection

Second, material selection

Select the appropriate material according to the performance requirements of the part, such as strength, hardness, and wear resistance.

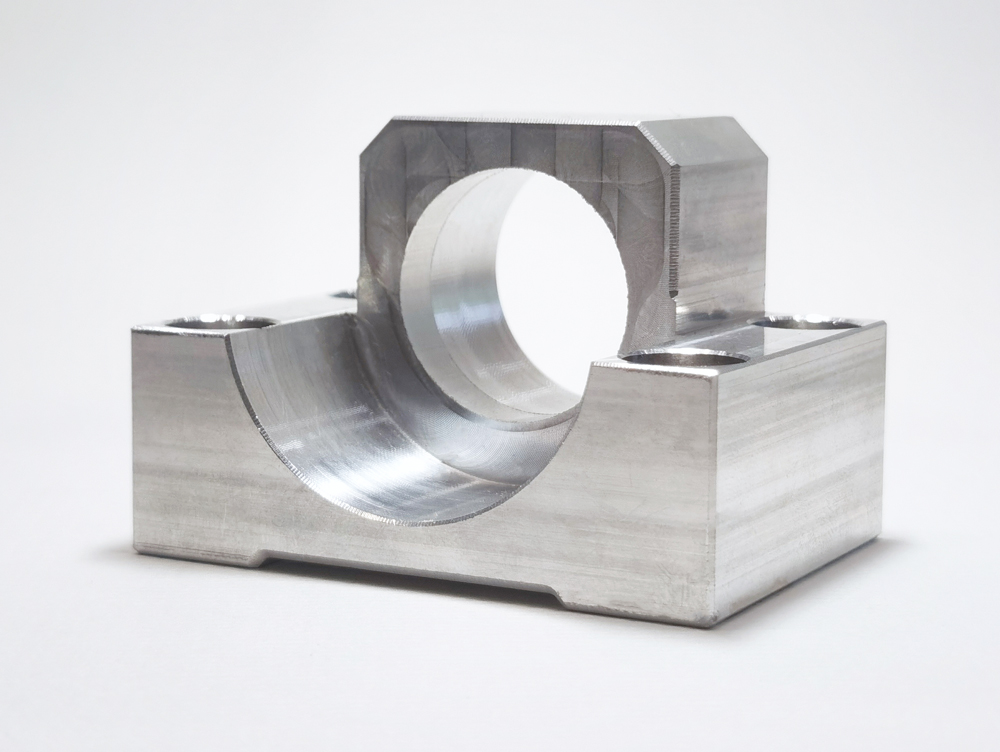

Precision mechanical parts processing usually uses high-strength, high-hardness alloy materials, which require rigorous material screening and quality inspection.

III. Blank preparation

The initial shape of the workpiece is obtained by means of casting, forging, profile cutting, etc.

The quality and dimensional accuracy of the blank have an important impact on subsequent processing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque