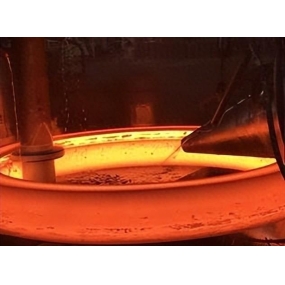

Sheet metal laser cutting is widely used in the cutting and processing of copper and aluminum products because of its high efficiency and high accuracy. Its main function is to divide the overall sheet metal and then bend and shape it. Different customer needs, different product processing materials have different thicknesses, which also leads to some engineers designing product thicknesses according to laser cutting in order to meet the capabilities of Sheet Metal Processing plants. Some new engineers will ask, What is the thickness range of sheet metal laser cutting copper plates?

When some customers find EMAR sheet metal processing, they generally ask how much the thickness of the laser cutting copper plate can be, because the thickness determines the product requirements. In years of experience in copper plate laser cutting production, the thickness range of the cutting hole in copper plate production 0.3-3 OMM. If the thickness of the copper bar is greater than this value, there will be burrs in the laser cutting, and the peripheral accuracy of the hole position will not be enough, which will affect the appearance of the copper parts.

Based on the above factors, in the R & D and design of copper products, engineers have to take into account the actual problems in processing and production, so as to design more scientific and technological product solutions. EMAR Hardware Products Co., Ltd. was established in 2005, the factory covers an area of 4000 square meters, the company has its own German TRUMPF 3040 laser cutting machine, numerical control bending machine, numerical control punch and other numerical control equipment readily available. EMAR focuses on sheet metal processing, sheet metal laser cutting, professional team, years of technical precipitation, you are trustworthy!

Based on the above factors, in the R & D and design of copper products, engineers have to take into account the actual problems in processing and production, so as to design more scientific and technological product solutions. EMAR Hardware Products Co., Ltd. was established in 2005, the factory covers an area of 4000 square meters, the company has its own German TRUMPF 3040 laser cutting machine, numerical control bending machine, numerical control punch and other numerical control equipment readily available. EMAR focuses on sheet metal processing, sheet metal laser cutting, professional team, years of technical precipitation, you are trustworthy!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque