Metal Products EMAR talks about the maintenance precautions of Metal Stamping punch and concave dies. Many people know that in the production of metal stamping dies, the machine needs to be maintained and carefully checked to improve the life of the die and thus improve production efficiency. jH6 Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, Hardware Processing, CNC

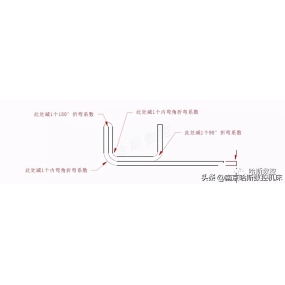

1. When the punch and concave die is disassembled, attention should be paid to the original condition of the mold, so that it can be easily restored during subsequent mold installation; if there is padding or displacement, the thickness of the gasket should be engraved on the parts and recorded. 2. When replacing the punch, try to insert the concave die of the material removal block smoothly, and try to insert whether the gap between the concave die and the concave die is uniform; when replacing the concave die, also try to insert and punch the gap evenly. 3. For the shortening of the punch after grinding, the gasket needs to be padded to reach the required length. Check whether the effective length of the punch is sufficient. Replace the broken punch to find out the cause, and at the same time check whether the corresponding concave has a chipping edge and whether the edge needs to be ground. 4. When assembling the punch, check whether the gap between the punch and the fixed block or the fixed plate is sufficient. If there is a pressing block, check whether there is any movement margin. The assembled die should be placed horizontally, and then placed on the concave die surface with a flat iron block. Tap it into place with a copper rod for metal products. Do not tilt it and force it in. The bottom of the die should be chamfered. After installation, check whether the concave die surface is flat with the die surface.  5. After the punch die and die core are assembled, it is necessary to check the material belt, whether each part is installed incorrectly or reversed, check whether the die and the die pad are installed inversely, whether the blanking hole is blocked, whether the new parts need to be stolen, whether the material needs to be stolen is enough, and whether the die needs to be locked tightly. 6. Metal product hardware stamping parts manufacturers should pay attention to the locking confirmation of the screws of the stripping plate. When locking, they should balance the force from the inside to the outside, and cross-lock. Do not lock a certain screw first, and then lock the other screw to avoid causing the stripping plate to tilt, causing the punch to break or the mold accuracy to be reduced. EMAR Hardware [] is a private enterprise specializing in the design and manufacture of various molds and fixtures such as hardware stamping, precision sheet metal parts, CNC processing and precision hardware molds. More hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping, metal stamping, hardware processing, CNC lathe processing Please call for consultation! jH6 Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, Hardware Processing, CNC

5. After the punch die and die core are assembled, it is necessary to check the material belt, whether each part is installed incorrectly or reversed, check whether the die and the die pad are installed inversely, whether the blanking hole is blocked, whether the new parts need to be stolen, whether the material needs to be stolen is enough, and whether the die needs to be locked tightly. 6. Metal product hardware stamping parts manufacturers should pay attention to the locking confirmation of the screws of the stripping plate. When locking, they should balance the force from the inside to the outside, and cross-lock. Do not lock a certain screw first, and then lock the other screw to avoid causing the stripping plate to tilt, causing the punch to break or the mold accuracy to be reduced. EMAR Hardware [] is a private enterprise specializing in the design and manufacture of various molds and fixtures such as hardware stamping, precision sheet metal parts, CNC processing and precision hardware molds. More hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping, metal stamping, hardware processing, CNC lathe processing Please call for consultation! jH6 Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, Hardware Processing, CNC

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque