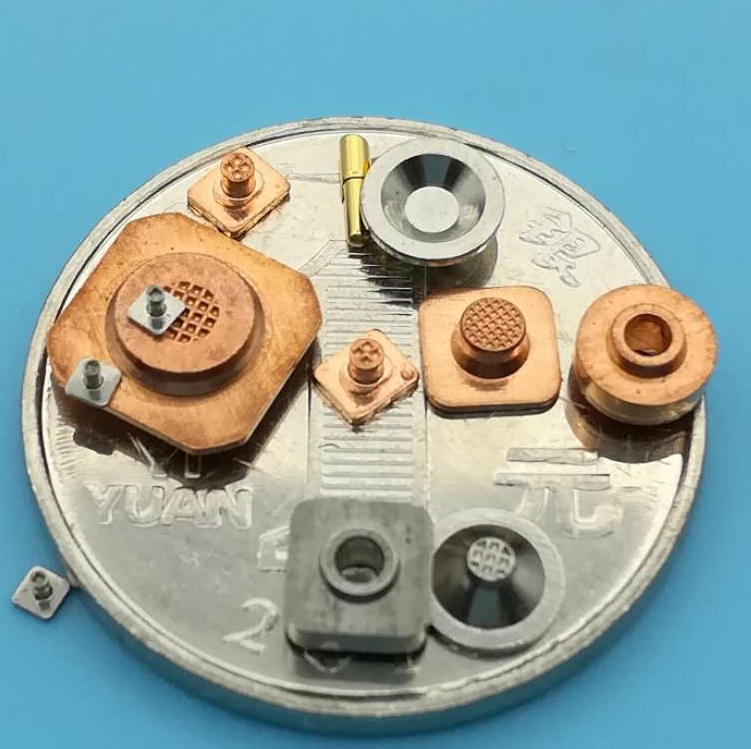

Metal Stamping, stretching, and cold extrusion are actually a kind of metal stamping, which is a way of talking about the development from simple metal stamping to more complex processing technology. Metal stamping initially consists of sheet metal or strip material stamped into the shape we need through a die. The main advantage is high efficiency and high yield. In the development of metal stamping, people found that the plate has more than just the effect of bending. By increasing the pressure and changing the lubrication of the metal surface, the plate can be elongated. By changing the mold structure, bowls and other shapes can be pulled out. This gradually formed the process of metal stretching. People‘s wisdom is infinite. Through the continuous improvement of the mold craftsman, various sensors such as high-precision temperature probes can now be stretched. Materials have also developed from iron plates to stainless steel, copper, etc. Nowadays, more and more industrial stretching products are used for sensors. After the stretching process became more and more mature, it was found that the material became better because of changing its internal structure and physical properties. Shrewd molders developed from stretching thin products to stretching thick products, not only improving metal surface lubrication and mold structure, but also standardizing, precision and diversification of products. On this basis, it developed into the current cold extrusion process. The original cold extrusion was to make simple automotive tools such as sleeves, and gradually developed into more complex structural parts such as gears. EMAR Hardware Co., Ltd. started research and production of cold extrusion process when it opened in 2006. Later, the research and development direction was miniature cold extrusion. After more than 10 years of hard work, we have achieved rich results. Now we can use high-speed punching presses to produce iron-nickel alloys, oxygen-free copper, stainless steel, pure aluminum and other materials by continuous die production. The production efficiency and precision of the products are among the best in this field in the country. Miniature cold extrusion products are mainly used in the field of communication hardware and electronics. Currently serving customers include Huawei, CITIC, Ericsson, Foxconn, Samsung and other top 500 companies in the world. In short, hardware stamping, stretching, and cold extrusion are all types of stamping, but stretching cold extrusion is a more complicated stamping.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque