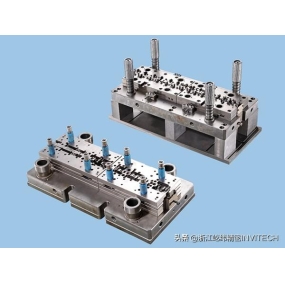

The rapid development of society and economy has also promoted the development of industrial enterprises towards the field of mechanical automation. The realization of the goal of Sheet Metal Processing automation is an important manifestation of industrialization development. Through the research and analysis of the development of sheet metal machining automation, it can provide theoretical support for practical development and promote the improvement of mechanical automation level. The methods of sheet metal processing are diverse, and it is more common in the application of continuous blanking methods. This processing method can be divided into multi-directional and single-directional processing. When processing multiple metal parts in a stacked shape in a single direction, the mechanical angles and functions set in this method are also different, which can achieve diverse processing effects. The application of the single stamping method in the sheet metal machining method can effectively realize the processing of metals distributed in arcs and pinholes to ensure the shape of metal products. In terms of the subsequent finishing method, it is the application method of grinding and finishing the post-processing of metal parts. The precise positioning of the processing and the effect of fine grinding are relatively good. The application of numerical control machine tools is more convenient, and the processing can effectively reduce costs. The application of numerical control machine tools can make the processing more convenient, and can effectively combine the given drawings to achieve the target metal forming processing. Numerical control machine tool sheet metal processing can greatly reduce the processing time and improve the overall efficiency of processing. The quality of the output product can be guaranteed, and the precision of processing has also been effectively improved, which can minimize the rate of defective products. In the automated processing of sheet metal machinery, through homogenization and the processing of the same batch, the quality can also be effectively balanced, and the manual screening procedure can be greatly simplified. The implementation of sheet metal raw material processing requires the use of automation technology, and the application of numerical control automation technology is more important. Processing through numerical control technology. In sheet metal processing, we must pay attention to the corresponding problems, first fix the processed metal materials, and avoid the shaking of the metal materials during processing due to grinding factors, resulting in the final product forming not meeting the actual requirements. Factors such as the time and sequence of material input should also be fully considered. Full attention should be paid to the machine tool cutting process, and the possible overlap and falling off of parts can be properly monitored during the processing process. The gap should be left as much as possible during the material placement process, so as to facilitate and reduce the mechanical operation error rate. In order to effectively ensure the orderly development of sheet metal processing, it is necessary to choose the appropriate processing time for the processing technology, and the precision should be guaranteed.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque