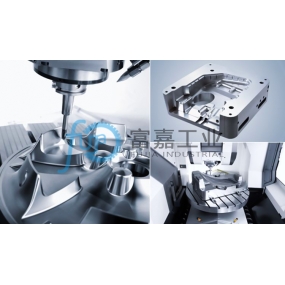

Stamping parts of the drawing process is a conventional production process, but to do a good job also need to pay attention to some things, stamping parts thinning drawing is generally a process of stretching or extrusion after forming, is a complete very thin-walled cup-shaped parts of the formation process. Next, let‘s learn about the characteristics of thinning and deep drawing in the stamping process and there are two ways of thinning and deep drawing in the stamping process.

The performance of the stretching process of stamped parts in production:

1. The characteristics of thinning and drawing during the stamping process are:

(1) The gap between the punch and the die is smaller than the thickness of the blank, and the blank is compressed when passing through the gap, resulting in a significant thinning phenomenon; this increases the height of the side wall, so it is called thinning deep drawing.

(2) The quality of the thinner drawing parts is high, and the wall thickness is relatively uniform.

(3) After the drawing parts become thinner, the residual stress is greater, and some even crack after storage in the warehouse, which can be removed by low temperature tempering.

2. There are two methods of thinning and drawing during the stamping process:

(1) The wall thickness becomes thinner and the inner diameter is also reduced - the deformation and stress are more complex, and the workpiece is prone to cracking, so this method is generally not used

(2) The wall thickness becomes thinner, and the inner diameter does not decrease significantly

The above is a little knowledge about the characteristics of thinning and drawing in the stamping process and the way of thinning and drawing explained by our company. If you need to know the little knowledge of other stamping parts, please continue to pay attention to us. We will explain it to you from time to time. Our factory produces stamping parts, automobile stamping parts, Metal Stamping parts, etc. all year round, with rich production experience, welcome to consult.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque