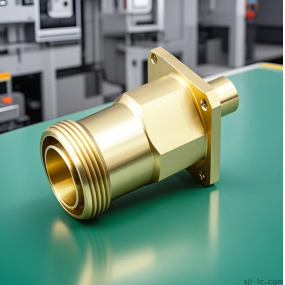

During the processing of non-standard equipment parts, there will be common questions such as accelerated tool wear, poor processing appearance integrity, and difficulty in chip removal, which seriously affect the quality, production cycle and processing cost of precision parts processing with such materials. According to the theory of metal technology, metal cutting, and non-standard equipment parts processing principles, the above material processing difficulties are analyzed, and a set of effective stainless steel data drilling, hinge, and boring processing skills are explored. China‘s machinery manufacturing industry is bound by skills and talents. It is difficult to compete with large companies in Europe, America and other regions in terms of skill innovation and commodity research and development. However, with the influx of foreign capital and the intensification of work competitions, domestic machinery parts processing has increased investment in independent development, and has achieved endless results, especially the mechanical measuring instrument production company has completed the breakthrough in digital display skills and digital hardware measuring tool products. For example, the 2-meter CNC gear measuring instrument successfully developed in China has become a precision measuring instrument with great competition strength in the world.

Other external forces have also provided excellent assistance to domestic machining companies in terms of skills. First, most non-standard equipment parts processing companies in China have introduced many foreign brands of precision machining equipment. There is no shortage of equipment imported from Japan and Germany in this center. With the assistance of external forces, it has also greatly improved the accuracy and fineness of the goods processed by non-standard equipment parts.

Other external forces have also provided excellent assistance to domestic machining companies in terms of skills. First, most non-standard equipment parts processing companies in China have introduced many foreign brands of precision machining equipment. There is no shortage of equipment imported from Japan and Germany in this center. With the assistance of external forces, it has also greatly improved the accuracy and fineness of the goods processed by non-standard equipment parts.

The processing of non-standard equipment parts requires an ultra-lubricated machining appearance and high machining accuracy, which requires a high standard life of the tool. Whether the tool is worn or not will be based on whether the machining appearance quality is reduced or not. The standard life of diamond tools is very high, and the tool wears very slowly during high-speed cutting. Therefore, in ultra-precision cutting, the cutting speed is not restricted by the tool life, which is different from the general cutting rules.

The cutting speed selected for non-standard equipment parts processing practice is often based on the dynamic characteristics of the ultra-precision machine tool used and the dynamic characteristics of the cutting system, that is, the rotational speed with the smallest vibration is selected. Due to the minimum surface roughness and the highest processing quality at this rotational speed. Obtaining a high-quality non-standard machining appearance is the primary question for non-standard equipment parts processing. Good use quality, especially good dynamic characteristics, and ultra-precision machine tools with small vibration can use high cutting speeds and can carry out processing power.

The selection of machining parameters for non-standard equipment parts mainly includes the selection of cutting tool viewpoints, cutting speed selection, cutting depth and feed speed selection, etc. From past experience, we know that when machining plastic materials, selecting a tool with a larger rake angle can effectively suppress the formation of chip accumulation. This is when the rake angle of the tool increases, the cutting force decreases, the cutting deformation is small, and the contact length between the tool and the chip is shortened, reducing the foundation of chip accumulation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque