EMAR Hardware Co., Ltd. has been working in precision cold extrusion processing and micro cold extrusion processing technology for many years, and broke through precision in 2008

EMAR Hardware Co., Ltd. has been working in precision cold extrusion processing and micro cold extrusion processing technology for many years, and broke through precision in 2008

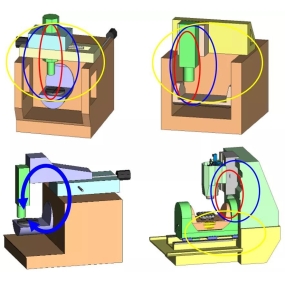

The key technology of cold extrusion processing and micro cold extrusion processing, changing the traditional cold extrusion embryo to the finished product "partial completion process" to cold extrusion

"Continuous high-speed stamping is completed" from the embryo to the finished product. Through the technical transformation of precision cold extrusion processing and micro cold extrusion processing, a breakthrough was made in one fell swoop

The monopoly position of the United States and Japan in micro-precision cold extrusion technology has enabled the precision and efficiency of precision cold extrusion processing and micro-cold extrusion processing

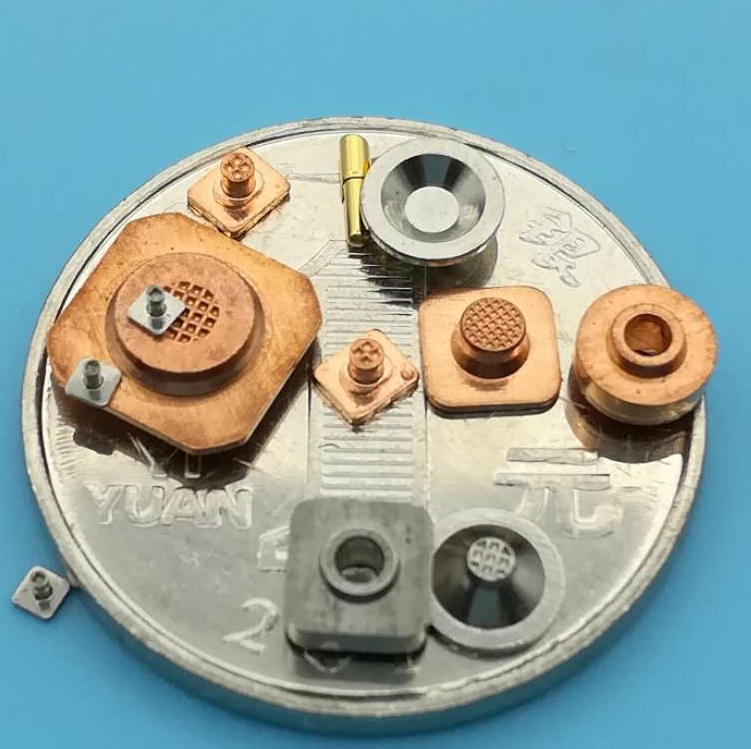

To greatly improve, the precision of the current product can reach 0.02mm, the efficiency is more than 5 times that of the traditional efficiency, and the maximum daily output of a single mode can reach

To the output of 25W pellets, our company‘s products are sold back to Japan‘s Panasonic, Sony, NEC and other companies. But with the miniature of electronic products

Our micro cold extrusion processing technology also follows "Moore‘s Law" and is becoming increasingly miniaturized and precision, EMAR precision cold extrusion processing and micro

The technology of type cold extrusion processing also comes from the strict requirements and challenges of customers, hoping to intentionally focus on precision cold extrusion processing and micro cold extrusion processing

Friends who have gone to the next level in technology participate in exchanges and discussions to improve people‘s manufacturing capacity and enhance national competitiveness.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque