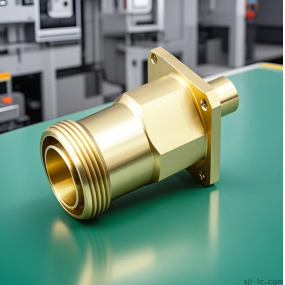

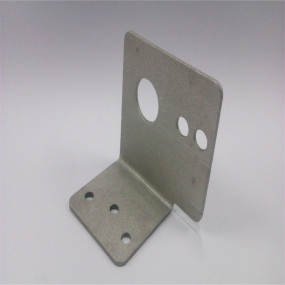

Sheet Metal Processing is a series of processes for bending, riveting, and welding of metal materials. The editor of sheet metal processing company will explain the problems encountered in the bending process in sheet metal processing and their solutions (2). Sheet metal shell processing

Problem 7: The bottom of the concave part is uneven

Problem 7: The bottom of the concave part is uneven

Reason:

1. The material itself is uneven

2. The contact area between the roof and the material is small or the jacking force is not enough

3. No jacking device in the die

Solution:

1. Leveling materials

2. Adjust the ejecting device to increase the ejecting force

3. Add a jacking device or correction

4. Add shaping process

Question 8: After bending, the axes of the two holes facing each other are misplaced

Reason:

The springback of the material changes the bending angle and the centerline is staggered

Solution:

1. Add the calibration process

2. Improve the bending die structure to reduce material rebound

Problem 9: Dimensional accuracy of hole position cannot be guaranteed after bending

Reason:

1. The unfolded size of the parts is wrong.

2. Material rebound

3. Unstable positioning

Solution:

1. Accurately calculate the blank size

2. Add a correction process or improve the bending die forming structure

3. Modify the processing method or increase the process positioning

Problem 10: The bending line is not parallel to the center of the two holes

Reason:

When the bending height is less than the minimum bending limit height, external expansion occurs in the bending part

Solution:

1. Increase the height of the bending parts

2. Improve the process method of bending parts

Question 11: After bending, the width direction is deformed, and the bent part has an arcuate deflection in the width direction

Reason:

Torsion and deflection due to inconsistent drawing and shrinkage in the width direction of the part

Solution:

1. Increase the bending pressure

2. Increase the calibration process

3. Ensure that the material has a certain angle to the bending direction

Problem 12: Pieces with notches flex downward

Reason:

The incision opens the two straight edges to the left and right, causing deflection at the bottom of the part

Solution:

1. Improve the structure of the parts

2. Increase the process allowance at the incision, connect the incisions, and then cut off the process allowance after bending

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque