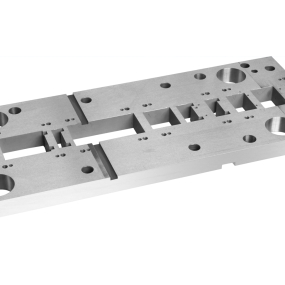

In business operations, there are only two ways to increase profit points. One is to develop more customers to improve sales performance, and the other is to save production costs to make the profit points of individual products higher. With these two methods as the starting point, I believe that we can achieve steady growth through every means of innovation and breakthrough. In terms of product processing technology, with the promotion of scientific and technological strength, many processing methods have been changed, and the changes in sheet metal laser cutting in recent years are very obvious. In the previous processing, sheet metal laser cutting could only be used to cut stainless steel products, but with the progress of equipment functions, the cutting of copper and aluminum materials can also be realized.

Sheet metal laser cutting high-efficiency working mode, this enterprise‘s product processing improves product quality, reduces manufacturing costs, and increases profit points for the enterprise‘s operation. Especially for the cutting and forming of large quantities of copper and aluminum materials, its benefits are more obvious.

The customer‘s transaction conversion rate is directly proportional to the cost performance of the product, especially some customers who are promoted through network marketing are more sensitive to the price factor. The same product drawings are sent to different manufacturers for quotations, and the price is relatively low, which is understandable. Without the production of the product, the customer can only use the price to distinguish the manufacturer. If your product adopts high-efficiency and low-cost sheet metal laser cutting in the manufacturing process, your product quotation will have an absolute advantage, which will greatly help you expand your customer base.

The customer‘s transaction conversion rate is directly proportional to the cost performance of the product, especially some customers who are promoted through network marketing are more sensitive to the price factor. The same product drawings are sent to different manufacturers for quotations, and the price is relatively low, which is understandable. Without the production of the product, the customer can only use the price to distinguish the manufacturer. If your product adopts high-efficiency and low-cost sheet metal laser cutting in the manufacturing process, your product quotation will have an absolute advantage, which will greatly help you expand your customer base.

EMAR is a Sheet Metal Processing plant with a certain influence in the industry, and the cost control should be relatively strict, so that the product can maintain a certain advantage in the industry competition, so as to gain the trust of more customers, and the enterprise can grow healthier. Sheet metal processing enterprises should constantly improve new processes, adopt new equipment, optimize production processes, and reduce the manufacturing cost of products. Our company‘s 8000W high-power laser cutting machine will provide you with comprehensive product manufacturing services.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque