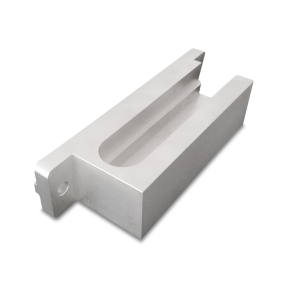

Precision five-axis machining is a high-precision, high-efficiency machining method that offers the following advantages:

1. High machining accuracy: Five-axis machining can simultaneously cut in multiple directions, enabling more complex shapes and curves to be machined, ensuring the accuracy and surface quality of the machined parts.

2. High processing efficiency: Five-axis machining can simultaneously cut in multiple directions, reducing the number of tool changes and improving processing efficiency; at the same time, the processing path can be optimized through an intelligent processing system, reducing processing time.

3. Long tool life: Due to the fact that five-axis machining can distribute the machining force more evenly, the wear of the tool is reduced, and the service life of the tool is extended.

4. Machining of complex structural parts: Five-axis machining can achieve the processing of complex structural parts without the need for multiple clamping workpieces or switching processing equipment, which greatly improves the processing efficiency and accuracy.

5. Save labor costs: Five-axis machining can achieve automated processing, reducing the need for manual intervention and operation, and reducing labor costs.

6. Wide range of applications: Five-axis machining is suitable for the processing of various materials, such as metals, plastics, ceramics, etc., to meet the processing needs of different industries and fields.

7. Flexibility: Five-axis machining can achieve cutting in different directions, and can flexibly adjust the machining path to meet the processing requirements of different workpiece shapes and sizes.

Overall, the precision five-axis machining of Shenzhen Machinery Processing Plant Fujia Industrial has the advantages of high precision, high efficiency, long life, wide application range, and strong flexibility, and can meet various complex processing needs. It is an important processing technology in modern manufacturing.

Overall, the precision five-axis machining of Shenzhen Machinery Processing Plant Fujia Industrial has the advantages of high precision, high efficiency, long life, wide application range, and strong flexibility, and can meet various complex processing needs. It is an important processing technology in modern manufacturing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque