In recent years, the Sheet Metal Processing industry has seen significant development. Some mechanical equipment shells, metal sheet metal parts, and chassis cabinets all require sheet metal processing. However, in the industry competition, the processing capabilities, processing efficiency, and processing technology level of enterprises are all factors that test the capabilities of a sheet metal processing manufacturer.

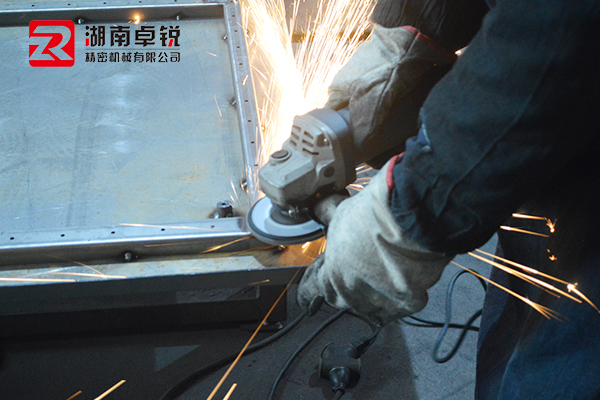

Sheet metal processing companies must place great importance on the technical processing capabilities of enterprises. Only by doing a good job in product quality can they win long-term cooperation with customers. An important process in sheet metal processing is grinding and polishing, which affects the appearance of the entire sheet metal parts. If customers place great importance on the surface treatment of sheet metal shell processing and the details, the grinding and polishing process must be professional.

Sheet metal grinding and polishing precautions include:

1. You must wear a protective mask (or protective mask) and glasses when working. Before work, check whether the grinding wheel is damaged, whether the safety protection device is in good condition, and whether the ventilation and dust removal device is effective. When installing, pay attention to the degree of compression of the nut. It should be pressed until the grinding wheel does not slide when moving. When there are multiple pressing screws, they should be tightened gradually and evenly in diagonal order.

1. You must wear a protective mask (or protective mask) and glasses when working. Before work, check whether the grinding wheel is damaged, whether the safety protection device is in good condition, and whether the ventilation and dust removal device is effective. When installing, pay attention to the degree of compression of the nut. It should be pressed until the grinding wheel does not slide when moving. When there are multiple pressing screws, they should be tightened gradually and evenly in diagonal order.

2. After the grinding wheel is installed, the protective cover must be reinstalled and then tested. Straight grinding wheels should be idled for 5 minutes. When the grinding wheel rotates, no obvious vibration is allowed. When grinding and polishing, the vacuum suction device should be started first, and the workpiece should be held firmly. The force should not be too strong. It is not allowed to use levers to push the components. It is strictly forbidden to stand on the front of the grinding wheel to prevent the grinding wheel from breaking and hurting people. Grinding wheels that are not specially used for end face grinding are prohibited from being polished with the end face. When using a handheld electric grinder for grinding and polishing, there must be a firm protective cover and a protective zero wire, or a leakage protector, and the following safety operating procedures for electric hand grinding wheels must be followed.

3. When more than two people are grinding and polishing at the same time, it is not allowed to work opposite each other in the same direction at the same time to prevent accidents. The concave and convex parts of the workpiece should be polished lightly, without excessive force, and the edges and corners of the workpiece should not be ground to prevent the grinding wheel from breaking and hurting people. After the work is completed, the power supply should be cut off to confirm that the grinding wheel has stopped before leaving the post.

Only professional processes and technical requirements can make perfect products. Although sheet metal processing parts do not have high-tech content, the detailed control of the product directly affects the customer‘s impression of the factory process. Only by achieving the details of sheet metal processing parts can we truly impress customers and make high-quality products to retain customers. With long-term cooperation and trust from customers, enterprises can better develop and grow.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque