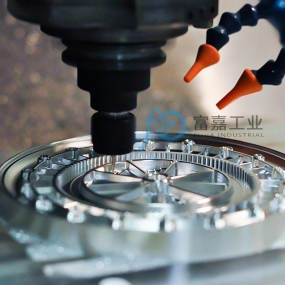

The overall layout of machining requires following certain principles. What are the errors and wear of its tool manufacturing? Please ask Shenzhen Precision Parts Machining to help us explain:

1. The dimensional accuracy of fixed-size tools (such as drills, reamers, keyway mills, and circular broaches, etc.) directly affects the dimensional accuracy of the workpiece.

1. The dimensional accuracy of fixed-size tools (such as drills, reamers, keyway mills, and circular broaches, etc.) directly affects the dimensional accuracy of the workpiece.

2. The shape accuracy of forming tools (e.g. forming turning tools, forming milling cutters, forming grinding wheels, etc.) will directly affect the shape accuracy of the workpiece.

3. The blade shape error of the developed tool (e.g. gear hob, spline hob, gear shaper, etc.) will affect the shape accuracy of the machined surface.

4. General tools (e.g. turning tools, boring tools, milling cutters) have no direct impact on their manufacturing accuracy, but they are prone to wear and tear.

Shenzhen precision parts processing machinery processing process specification design principles:

1. The designed process specification should be able to ensure the processing quality of machine parts (or the assembly quality of the machine), meeting the technical requirements specified on the design drawings.

2. The process should be made more productive so that the product can be put on the market as soon as possible.

3. Try to reduce manufacturing costs.

4. Pay attention to reducing the labor intensity of workers and ensure production safety.

Scope of application of precision machining:

1. Processing of various metal parts;

2. Sheet metal, boxes, and metal structures.

3. Mechanical processing of titanium alloys, superalloys, and non-metals.

4. Design and manufacture of wind tunnel combustion chamber.

5. Non-standard equipment design and manufacturing;

6. Mold design and manufacturing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque