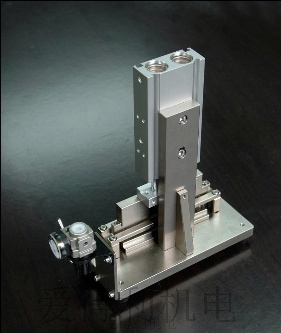

Shenzhen Fujia Industrial Co., Ltd. now owns CNC Machining center, numerical control lathe, automatic lathe and other series processing facilities as well as altimeter, two-dimensional element, mass spectrometer, hardness tester, micron micrometer and other testing equipment, specializing in medical, electronics, optics, communications, toys, plastics and other Shenzhen CNC processing, numerical control lathe parts precision hardware parts development and production.

We must have a plan for the deepening impact of some unique environments, because what we need to know is that we must make adjustments, such as the measuring ruler we make, which requires a specific regulation during processing, and the errors that occur must also be within a certain range.

In the structure of CNC precision parts machining, the parts and components that have been mastered and produced should be used as much as possible, especially the standard parts should be used as much as possible. In the same structure, the same parts should be used as much as possible. Parts should be interchangeable, and in the case of high precision requirements, adjustment links can be designed, and selective assembly should not be used as much as possible.

Structural craftsmanship is related to specific production conditions. A structure with good craftsmanship in one production condition may not be good in another production condition. General principles for improving structural craftsmanship are as follows.

Structural craftsmanship is related to specific production conditions. A structure with good craftsmanship in one production condition may not be good in another production condition. General principles for improving structural craftsmanship are as follows.

CNC precision parts machining is convenient for manufacturing blanks. The manufacturing methods of blanks include casting, forging and welding, etc., which should be selected according to the use requirements of mechanical parts, production batch and specific manufacturing conditions. Easy to clamp work; Minimize the machining area; Try to use standard tools and reduce the type of tools; Easy to enter and exit the tool; Reasonable selection of dimensional tolerances and surface roughness of parts.

Precision machining, as a type of processing, its main application field is in some large machines, and some of our special products also need such processing. Compared with general processing, such processing is more prominent at a certain level. Our application is close to our regular use, and it is also a series of specific losses that we can understand in the environment.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque