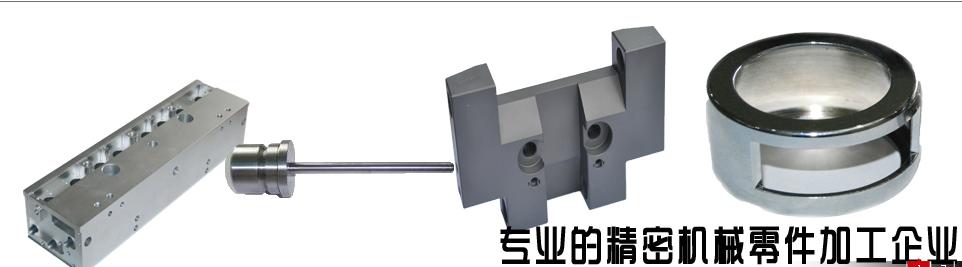

1. Drawings, that is, product assembly drawings and part drawings, are necessary for all precision parts processing processes to begin.

2. The quality acceptance standard of the product, and the degree to which the product is processed to be qualified, is a crucial criterion, so there must be an indicator in advance as a reference.

2. The quality acceptance standard of the product, and the degree to which the product is processed to be qualified, is a crucial criterion, so there must be an indicator in advance as a reference.

3. The annual production plan of the product. This is the overall production specification of an industry or a product, such as what kind of materials to use, what standards the material content should meet, and what market requirements the product quality should meet.

4. Clarify the production conditions. Generally speaking, some lathe equipment, process equipment specifications, workers‘ technical level, equipment performance, and factory production and processing capabilities used in precision parts processing plants.

5. Design manuals and related standards are mainly for process specification design and process equipment design.

6. At present, some relevant information on new precision parts processing and manufacturing technologies at home and abroad, the so-called know yourself, know your enemy, and you are not in danger. Although machining is not a battle, the key to competition among industries is technological competition.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque