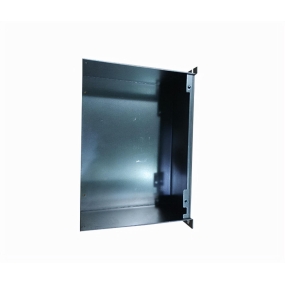

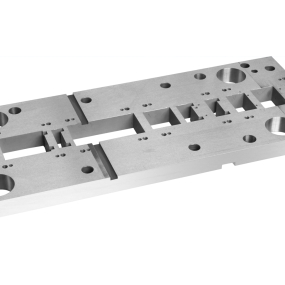

Fiber laser cutting and processing of external orders, high equipment efficiency, unit price advantage, quality advantage, delivery advantage, a large number of batch cutting orders, Germany‘s TRUMPF 8000W fiber disc laser cutting and cutting, robot robot automation factory is more willing to choose this way of processing, because it can save time and cost.

The use of laser cutting for robotic hardware is the production method adopted by most manufacturers, and it can be completed efficiently. The cutting of aluminum and stainless steel plates for robotic arms can improve the efficiency and save costs for the manufacture of products, because if the robotic sheet metal parts are stamped with hardware, the die cost will be very high, and the equipment required for stamping large-scale hardware parts is also different. This kind of manufacturing cost will be very high.

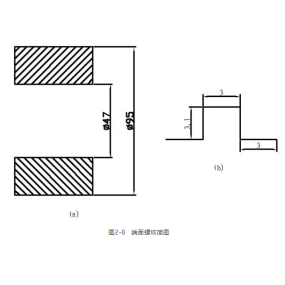

Copper bars using fiber laser cutting processing is more advantageous!

Copper bars are used in new energy electric vehicles, energy storage batteries, power cabinets, etc. Copper bars are the choice for conductive connections of many products. They have good electrical conductivity, high cost performance and strong oxidation resistance. In the traditional processing method, copper bars are processed by Metal Stamping, but in this regard, stamping dies need to be opened, which is low in cost, especially for those products that are not large in quantity and urgently needed. If laser cutting is used, it will save time and cost.

When laser cutting copper bars, only a flat drawing is required, which is imported into a computer program, and the laser cutting equipment can complete the cutting task according to the path of the drawing. The speed is very fast, and the cutting surface is smooth, which can completely replace the copper bar effect of metal stamping.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque