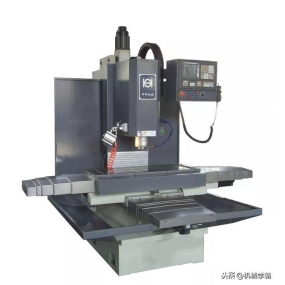

In the batch production of hardware processing hardware parts processing, due to the high precision and short delivery time of the workpiece, the work efficiency of the equipment is the top priority of production and processing. Being able to grasp the simple basic knowledge can not only improve the productivity of hardware parts processing, but also reduce the failure rate of the equipment during use. RDN Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Metal Stamping, Metal Processing, CNC

Here are some CNC precision hardware parts machining basic knowledge to share with the netizens: 1. Chip control, the chips are wound around the tool or machined parts for a long continuous cutting. Generally caused by low feed, low and/or shallow cutting depth of the groove shape.  2. The appearance quality of the hardware machining, the appearance and feel are "hairy", which does not meet the requirements of the service. 3. Burr formation, when the cutting is separated from the workpiece, the burr is formed at the end of the cutting. 4. Metal machining oscillation, high radial cutting force, the reason: the oscillation or shaking scratches caused by the tool or tool device. Generally presented in the use of boring bars for internal machining. This information is provided by EMAR hardware manufacturers, and more hardware factories, hardware products, metal products, precision sheet metal, metal processing, sheet metal factories, metal stamping, metal stamping, metal processing, CNC lathe processing, and other information. We warmly welcome people from all walks of life to visit our factory for negotiation and guidance. We will serve you wholeheartedly.

2. The appearance quality of the hardware machining, the appearance and feel are "hairy", which does not meet the requirements of the service. 3. Burr formation, when the cutting is separated from the workpiece, the burr is formed at the end of the cutting. 4. Metal machining oscillation, high radial cutting force, the reason: the oscillation or shaking scratches caused by the tool or tool device. Generally presented in the use of boring bars for internal machining. This information is provided by EMAR hardware manufacturers, and more hardware factories, hardware products, metal products, precision sheet metal, metal processing, sheet metal factories, metal stamping, metal stamping, metal processing, CNC lathe processing, and other information. We warmly welcome people from all walks of life to visit our factory for negotiation and guidance. We will serve you wholeheartedly.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque