Sheet metal fabrication is a set of manufacturing processes that process sheet metal into functional components. For this guide, we have divided the processes into three categories: cutting, deformation, and assembly.

Common sheet metals include steel, stainless steel, aluminum, zinc, and copper, and the sizes of these materials are typically between 0.006 and 0.25 inches (0.015 and 0.635 cm). Thinner specifications are more malleable, while thicker specifications may be more suitable for heavy parts with intense applications.

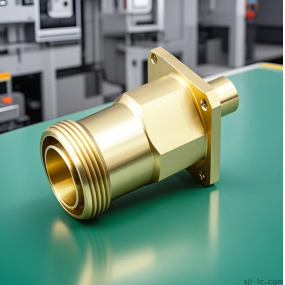

For parts that are partially flat or hollow, sheet metal fabrication can be a cost-effective alternative to processes such as casting and machining. The process is also fast and generates minimal material waste.

Sheet metal manufacturing is widely used in industrial and consumer parts, as well as in specialized industries such as automotive, aerospace, energy, and robotics.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque