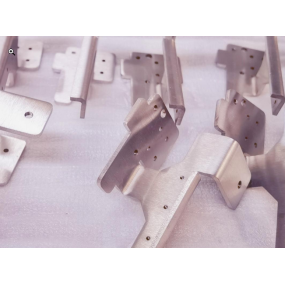

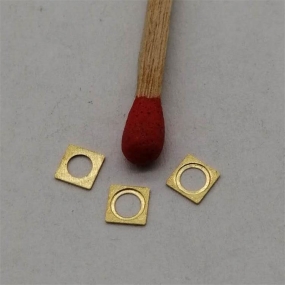

On Saturday, August 19, 2017, it was time for the EMAR meeting to learn again. The meeting was organized by EMAR Deputy General Manager Li Wenwu. Vice President Li Wenwu first emphasized the importance of learning, pointing out that if we do not learn now, we will not be able to keep up with the pace of customer transformation and upgrading. Now many of our customers are pursuing automated production of products, which requires our product standardization. The product defect rate should be reduced to less than 1PPM. We must ensure the standardization of molds and production processes. We must make products in strict accordance with customer requirements. Otherwise, we will be eliminated during this customer transformation and upgrading process. Finally, Vice President Li Wenwu commended the mold design department, thanking this department for its perseverance in learning and breaking through one design problem after another, especially the technical improvement of the dual process of special-shaped stretching, right-angle stretching, and stretching cold extrusion, which has won a lot of praise from customers.

On Saturday, August 19, 2017, it was time for the EMAR meeting to learn again. The meeting was organized by EMAR Deputy General Manager Li Wenwu. Vice President Li Wenwu first emphasized the importance of learning, pointing out that if we do not learn now, we will not be able to keep up with the pace of customer transformation and upgrading. Now many of our customers are pursuing automated production of products, which requires our product standardization. The product defect rate should be reduced to less than 1PPM. We must ensure the standardization of molds and production processes. We must make products in strict accordance with customer requirements. Otherwise, we will be eliminated during this customer transformation and upgrading process. Finally, Vice President Li Wenwu commended the mold design department, thanking this department for its perseverance in learning and breaking through one design problem after another, especially the technical improvement of the dual process of special-shaped stretching, right-angle stretching, and stretching cold extrusion, which has won a lot of praise from customers.

Attachment download (1): EMAR Hardware Organization Learning .jpg

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque