Aluminum plates are very prone to natural oxidation and reduction reactions with gases, causing air oxidation spots. So what should a precision Sheet Metal Processing plant do to maintain the surface from oxidative erosion? The following sheet metal processing companies give you tips to avoid oxidative erosion in precision sheet metal processing.

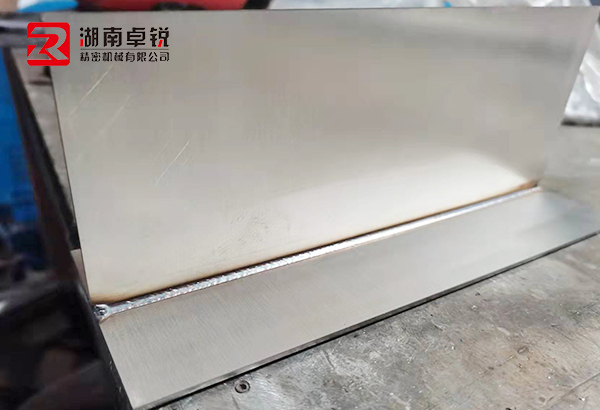

In the production process of precision sheet metal processing, especially the mirror aluminum plate, it is usually laser-cut with some other metal materials. During the production process, some metal materials such as magnesium, zinc or copper are added reasonably, and this metal material will quickly work with aluminum, resulting in a product commonly referred to as aluminum alloy profile in the industry.

In the production process of precision sheet metal processing, especially the mirror aluminum plate, it is usually laser-cut with some other metal materials. During the production process, some metal materials such as magnesium, zinc or copper are added reasonably, and this metal material will quickly work with aluminum, resulting in a product commonly referred to as aluminum alloy profile in the industry.

The equipment function and impact toughness of this aluminum alloy profile are good, and even the application standard for it is usually much larger than the original, but in view of its application process, it is very easy to react with oxygen in the air, whether it is its finished mirror aluminum plate or metal brushed aluminum plate, it must be oxidized and pretreated at the time of production to avoid secondary oxidation in daily applications. Naturally, they will continue to cover the surface with a protective film during production, thus preventing the surface from touching or being scratched by the atmosphere.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque