As an important part of the manufacturing industry, the development of hardware processing technology has witnessed a huge transformation from crude to fine, from artificial to intelligent. Traditional forging technology, as a long-standing processing method, relies on the experience and physical strength of craftsmen to shape metal products by means of hammering, forging, etc. Although this method is exquisite, it is inefficient and difficult to ensure product consistency and high precision.

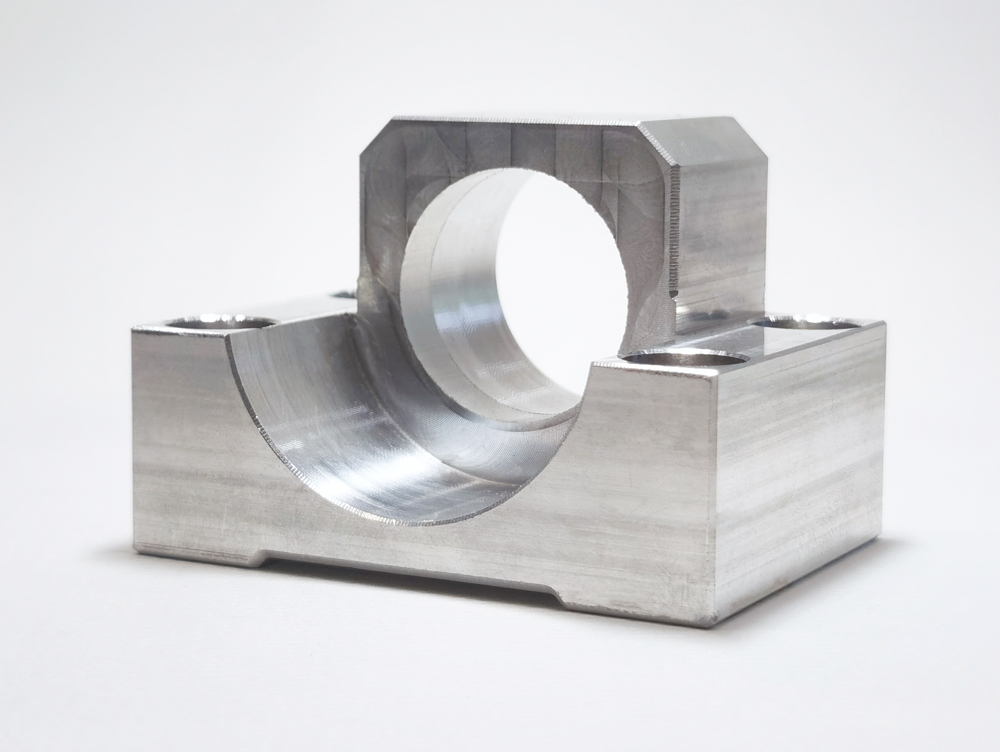

With the progress of science and technology, especially the rapid development of numerical control technology, hardware processing technology has ushered in a revolutionary upgrade. Precision numerical control processing, with its high efficiency, precision and flexibility, has gradually become the mainstream of the industry. Through pre-programmed computer instructions, numerical control machine tools can automatically complete complex cutting, drilling, milling and other processes, not only greatly improve the processing efficiency, but also ensure the accuracy of product size.

With the progress of science and technology, especially the rapid development of numerical control technology, hardware processing technology has ushered in a revolutionary upgrade. Precision numerical control processing, with its high efficiency, precision and flexibility, has gradually become the mainstream of the industry. Through pre-programmed computer instructions, numerical control machine tools can automatically complete complex cutting, drilling, milling and other processes, not only greatly improve the processing efficiency, but also ensure the accuracy of product size.

Enterprises need to invest in the introduction of advanced numerical control equipment, while training or introducing professionals with numerical control programming and operation skills. In addition, in order to adapt to the high-precision requirements of numerical control processing, the original production process, quality inspection standards and even management concepts need to be adjusted and optimized accordingly.

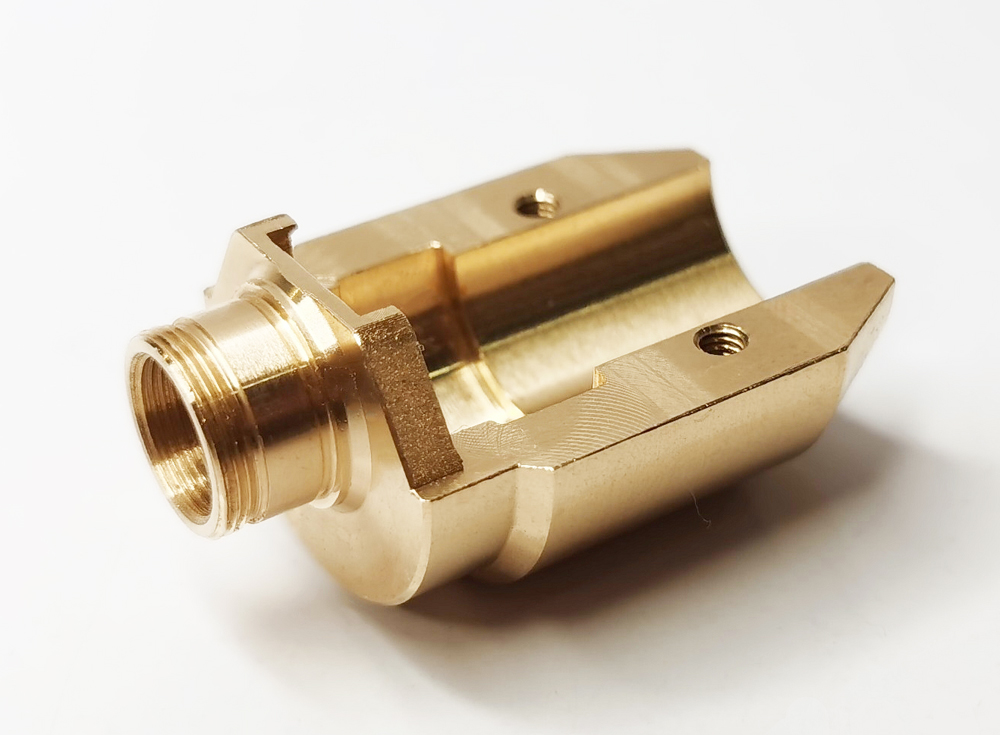

This transformation has brought not only a leap in production efficiency and product quality, but also a significant improvement in the competitiveness of enterprises. Precision numerical control processing enables hardware products to meet broader and higher-end market needs, such as aerospace, precision instruments, medical apparatus and other fields. At the same time, it also opens up new business areas for enterprises, such as customized, small batch, multi-variety production mode, enhancing market adaptability.

This transformation has brought not only a leap in production efficiency and product quality, but also a significant improvement in the competitiveness of enterprises. Precision numerical control processing enables hardware products to meet broader and higher-end market needs, such as aerospace, precision instruments, medical apparatus and other fields. At the same time, it also opens up new business areas for enterprises, such as customized, small batch, multi-variety production mode, enhancing market adaptability.

In short, the transformation from traditional forging to precision numerical control is an inevitable trend in the development of hardware processing technology. It not only represents technological progress, but also an important symbol of industrial upgrading and quality improvement. Facing the future, continuous technological innovation and personnel training will be the key to promoting the sustainable development of the hardware processing industry. With the continuous evolution of numerical control technology, the hardware processing industry will surely usher in a broader development prospect.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque