Due to its excellent electrical conductivity and strong oxidation resistance, copper bars are used in many industries and products. The internal conductive connections of various motor gauges are processed by hard row, because if the quantity is relatively large, it can be produced by developing stamping mode. If the stamping equipment is continuously processed and automated, the processing speed is very fast, and the manufacturing cost is very low. However, when some products are applied, there is no large-scale production. If the hardware stamping die is developed, the mold opening cycle is long and the mold cost is high, so it is not cost-effective. At this time, laser cutting can be used.

In general, in the case where the current and voltage can be reached, if only the conductive connection is used, it is more economical to use the hard copper bar, because the processing method of the hard copper bar is simple, the manufacturing cost is low, and in the case of corner or turn, if the enterprise does not want to develop a Metal Stamping die, laser cutting can be used.

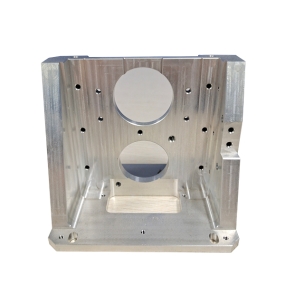

The  hard copper bar solution requires a metal stamping die, and the right-angle turning part. If the hard copper bar is to achieve the effect shown in the figure, a large copper plate needs to be stamped and formed, which is very wasteful of materials and the production cost will be very high. If you don‘t want to waste materials, you can use laser cutting processing. You can draw the product processing drawings according to the size of the cut product on a copper plate, and the laser cutting equipment will complete the cutting of the copper plate according to the specified line. This can also complete the copper bar production in the picture above, and save materials as much as possible. This processing method still requires more regular products, so that the utilization rate of the copper plate is good and the cost is relatively low.

hard copper bar solution requires a metal stamping die, and the right-angle turning part. If the hard copper bar is to achieve the effect shown in the figure, a large copper plate needs to be stamped and formed, which is very wasteful of materials and the production cost will be very high. If you don‘t want to waste materials, you can use laser cutting processing. You can draw the product processing drawings according to the size of the cut product on a copper plate, and the laser cutting equipment will complete the cutting of the copper plate according to the specified line. This can also complete the copper bar production in the picture above, and save materials as much as possible. This processing method still requires more regular products, so that the utilization rate of the copper plate is good and the cost is relatively low.

Overall, the use of laser cutting equipment to cut copper bars results in a relatively low processing cost, as it saves the cost of die and labor for metal stamping. Laser cutting equipment can be used to complete the processing and production tasks.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque