In precision parts processing, the division of processes and steps is quite clear, and it is fine to each link. The general processing industry divides tasks according to processes or steps. Each person is responsible for a part, or a team of people is responsible for a part. The division of labor is clear and the tasks are clear.

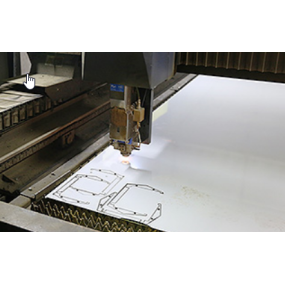

The division of precision parts processing procedures is carried out with reference to the processed parts and the designed processing technology. In the numerical control machine tool for precision parts processing, the process can be relatively centralized, and most or all of the processes can be completed as much as possible in one clamping. First of all, according to the part pattern, consider whether the processed parts can be processed on a numerical control machine. If not, decide which part is processed on the numerical control machine and which part is processed on other machines, that is, the processing process of the parts is divided. The division of processes and steps should be comprehensively considered according to the structural characteristics and technical requirements of specific parts.

The division of precision parts processing procedures is carried out with reference to the processed parts and the designed processing technology. In the numerical control machine tool for precision parts processing, the process can be relatively centralized, and most or all of the processes can be completed as much as possible in one clamping. First of all, according to the part pattern, consider whether the processed parts can be processed on a numerical control machine. If not, decide which part is processed on the numerical control machine and which part is processed on other machines, that is, the processing process of the parts is divided. The division of processes and steps should be comprehensively considered according to the structural characteristics and technical requirements of specific parts.

General process division method:

The division of work steps is mainly considered from the two aspects of machining accuracy and efficiency. In a precision part machining process, different tools and cutting amounts are often required to process different surfaces. In order to facilitate the analysis and description of more complex processes, the process is subdivided into work steps.

The principle of step division:

1. The same surface is completed in sequence by roughing, semi-finishing, and finishing, or all the machined surfaces are separated by roughing first and then finishing.

2. For parts with both milled surfaces and boring holes, the surface can be milled first and then boring. Dividing the steps according to this method can improve the accuracy of the hole. Because of the large cutting force during milling, the workpiece is prone to deformation. Milling the surface first and then boring, so that it has a period of time to recover, reducing the impact of deformation on the accuracy of the hole.

3. Divide the steps according to the tool. The turnaround time of the precision parts processing machine tool table is shorter than the tool change time. Dividing the steps according to the tool can be used to reduce the number of tool changes and improve the processing efficiency.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque