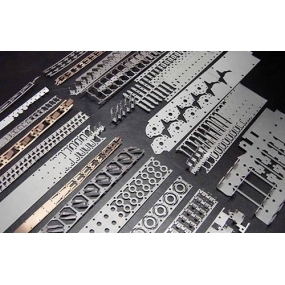

What are the aspects of the processing technology of precision parts? The processing technology of precision parts involves a wide range, and this is only analyzed from the two aspects of processing possibility and convenience. Mainly, the size data on the parts processing drawings should conform to the principle of programming convenience

(1) The dimensioning method on the part drawing should be adapted to the characteristics of numerical control processing. On the precision part machining drawing, the size should be quoted on the same basis or the coordinate size should be directly given.

(1) The dimensioning method on the part drawing should be adapted to the characteristics of numerical control processing. On the precision part machining drawing, the size should be quoted on the same basis or the coordinate size should be directly given.

1. This labeling method is both convenient for programming and for the coordination of dimensions, which brings great convenience in maintaining the consistency of design benchmarks, process benchmarks, test benchmarks, and programming origin settings.

2. Since part designers generally consider assembly and other use characteristics in dimensional marking, they have to use a partially scattered marking method, which will bring many inconveniences to process arrangement and numerical control processing.

3. Due to the high machining accuracy and repeated positioning accuracy of precision parts, the use characteristics will not be damaged due to large accumulated errors. Therefore, the local scattered labeling method can be changed to the same reference size or the coordinate size can be directly given.

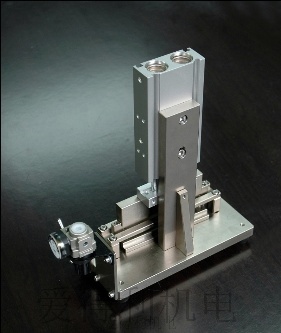

(2) Calculate the basis point or node coordinates when programming manually. In automatic programming, precision part machining defines all the geometric elements that make up the contour of the part. Therefore, when analyzing the part drawing, it is necessary to analyze whether the given conditions of the geometric elements are sufficient.

For example, arcs and straight lines, arcs and arcs are tangent on the drawing, but according to the dimensions given on the drawing, when calculating tangent conditions, they become intersected or separated. Due to the insufficiency of the geometric elements that make up the precision parts, it is impossible to start programming. When encountering this situation, it should be negotiated with the part designer to solve it.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque