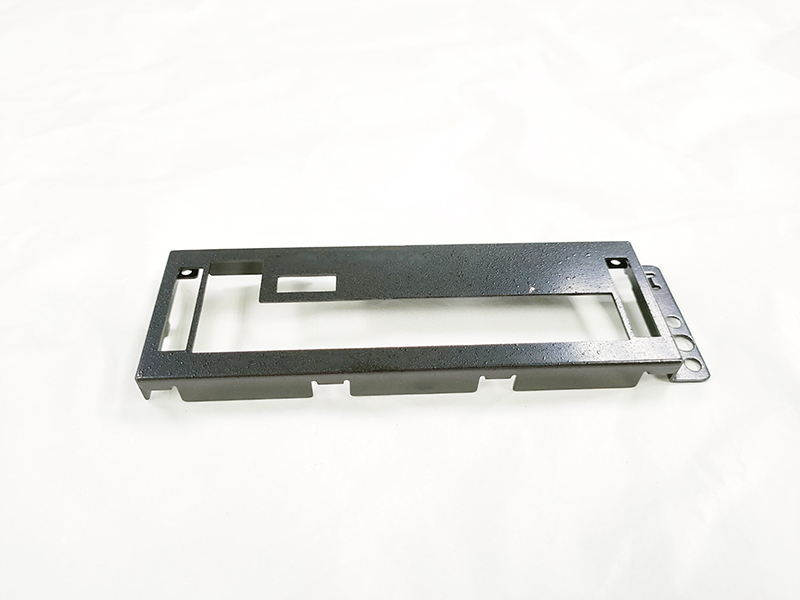

Metal Stamping is a new type of processing method. The metal parts processed by this process have high precision, beautiful appearance and accurate size. So now many metal parts are stamped. So what factors will affect the use of these processing methods? Let‘s take a look and understand. DE6 Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, CNC

1. Die problems, stamping processing requires the use of molds for processing. The molds it uses are generally specialized. Sometimes a messy part requires several sets of molds to be processed and formed, and the precision of mold manufacturing is high, the skill requirements are high, and it is a skill-intensive product. Therefore, only in the case of large production batches of stamping parts can the advantages of stamping processing be fully reflected, so as to achieve better economic benefits. 2. Safety issues. There will be some safety problems in stamping processing. There will be some hazards in stamping processing, such as noise and vibration, and operator safety accidents occur from time to time. However, these problems are not entirely due to the stamping process and the die itself, but mainly due to the traditional stamping equipment and backward technical operation. With the advance of scientific skills, especially the development of computer skills, followed by the advancement of mechatronics skills, these problems will be solved quickly and perfectly. Hardware stamping.  Another is high-strength steel stamping. Today‘s high-strength steel and ultra-high-strength steel have well realized the lightweight of vehicles, improved the collision strength and safety functions of vehicles, and thus become an important development direction of automotive steel. However, with the progress of sheet metal strength, the traditional cold stamping process simply breaks during the forming process, unable to meet the processing requirements of high-strength steel plates. In the case that the forming conditions cannot be met, the hot stamping forming technology of ultra-high-strength steel sheets is gradually being studied internationally. This technology is a new process that summarizes the forming, heat transfer and microstructure phase transformation. It mainly uses the characteristics of high-temperature austenite, the plasticity of the sheet increases, yielding, and the strength decreases, and the forming process is carried out through the mold. However, hot forming requires in-depth research on process conditions, metal phase transformation, and CAE analysis skills. Now this technology is monopolized by foreign manufacturers, and the domestic development is slow. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping processing, metal stamping processing, hardware processing, CNC lathe processing and other information, sincerely welcome people from all walks of life to visit our factory to negotiate and guide, we will serve you wholeheartedly.

Another is high-strength steel stamping. Today‘s high-strength steel and ultra-high-strength steel have well realized the lightweight of vehicles, improved the collision strength and safety functions of vehicles, and thus become an important development direction of automotive steel. However, with the progress of sheet metal strength, the traditional cold stamping process simply breaks during the forming process, unable to meet the processing requirements of high-strength steel plates. In the case that the forming conditions cannot be met, the hot stamping forming technology of ultra-high-strength steel sheets is gradually being studied internationally. This technology is a new process that summarizes the forming, heat transfer and microstructure phase transformation. It mainly uses the characteristics of high-temperature austenite, the plasticity of the sheet increases, yielding, and the strength decreases, and the forming process is carried out through the mold. However, hot forming requires in-depth research on process conditions, metal phase transformation, and CAE analysis skills. Now this technology is monopolized by foreign manufacturers, and the domestic development is slow. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping processing, metal stamping processing, hardware processing, CNC lathe processing and other information, sincerely welcome people from all walks of life to visit our factory to negotiate and guide, we will serve you wholeheartedly.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque