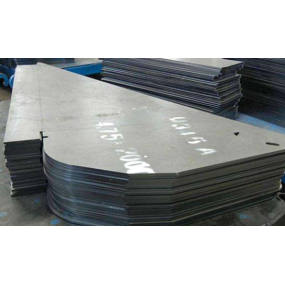

Sheet Metal Processing Description The conventional sheet metal processing process is to use: shear-punch-bend-welding process or flame plasma cutting-bend-welding process. In the face of multi-variety, small batch, customized, high-quality, short delivery orders, it shows obvious incompatibility. Laser cutting technology emerged as an alternative to "shear-punch" and has the characteristics of flexibility and high flexibility. At the same time, most people also think that its cost is high. Therefore, it is often used in the manufacture of special-shaped (or complex-shaped) workpieces and samples (single piece or very small batch). But when small batch manufacturing is becoming more and more popular, the demand for laser cutting is also increasing.

Sheet metal processing analysis When re-examining the new sheet metal processing technology: laser cutting-bending-welding/riveting, due to the high flexibility and high precision of laser cutting, the maturity and popularization of 3D design technology, users can benefit from the new design and new process, thus achieving the requirements of reducing costs and shortening the construction period. Therefore, the new sheet metal process starts from the design: design, laser cutting, bending, welding/riveting. The following are a few examples to illustrate the characteristics of the new process.

1) Under the traditional process, the workpiece is composed of several parts. Now, one cutting and bending are completed. The purpose of reducing processes, shortening construction periods and reducing costs is achieved

2) Under the traditional process, special fixtures are configured for welding. Now a process similar to woodworking tenons is used between components, which is accurate in positioning, time-saving, simple in welding fixtures, and small in product deformation. The purpose of shortening the construction period, reducing costs, and improving quality is achieved.

3) The multi-bending process has become more popular in the domestic box manufacturing industry. The advantage is that the traditional reinforcing ribs are omitted. It has its unique design and process. So as to achieve the purpose of high product quality and low manufacturing cost. In the actual process, it is also necessary to cooperate with spot welding.

4) Using the laser‘s fine slitting and high precision, one cut (with micro-connection), with four bends, completes four workpieces. It breaks through the design idea under the traditional process and achieves the purpose of shortening the construction period and reducing the cost.

5) Due to the use of a tenon structure, the entire process can be completed after the workpiece is bent and matched with the spot welding process. The workpiece has small deformation and does not need to be shaped or polished before spraying.

Due to the characteristics of the new process, advanced sheet metal equipment software support and design, laser cutting process, bending process. It supports two-dimensional part design, pipe part design, bending workpiece design (only supports Baichao‘s bending machine), and three-dimensional graphics are unfolded. And through the standard computer network, the numerical control program is transmitted to the designated machine.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque