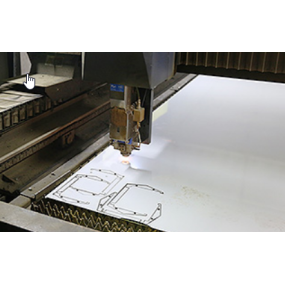

Hardware products in the metal precision machining, there is often a situation of high scrap rate. Now the stamping industry competition is very fierce, profit margins are also compressed very severely, if the scrap rate remains high, it is very likely that an order is not only not profitable but also lost money. Then it is particularly important to reduce the problem of high scrap rate of metal precision machining. J8r Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, Hardware Processing, CNC

1. Raw materials are the first guarantee for qualified metal precision machining. If the hardness and appearance of raw materials do not meet the quality requirements, then the corresponding precision stamping parts scrap rate will definitely be too high. 2. Hardware products should strictly abide by all links specified in the process regulations.  3. The tooling equipment such as presses and dies used should be guaranteed to work under normal working conditions, and daily testing and maintenance should be carried out at all times. 4. Hardware products should be ensured during the stamping process. The mold cavity should be clean, the workplace should be organized, and the workpieces after hardware precision machining should be neatly arranged. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping, hardware stamping, hardware processing, CNC lathe processing and other information, sincerely welcome people from all walks of life to visit our factory to negotiate and guide, we will serve you wholeheartedly. J8r Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, CNC

3. The tooling equipment such as presses and dies used should be guaranteed to work under normal working conditions, and daily testing and maintenance should be carried out at all times. 4. Hardware products should be ensured during the stamping process. The mold cavity should be clean, the workplace should be organized, and the workpieces after hardware precision machining should be neatly arranged. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping, hardware stamping, hardware processing, CNC lathe processing and other information, sincerely welcome people from all walks of life to visit our factory to negotiate and guide, we will serve you wholeheartedly. J8r Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, CNC

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque