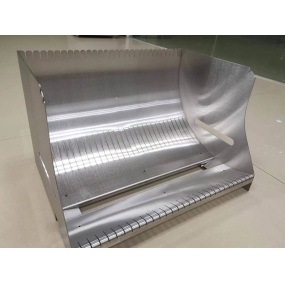

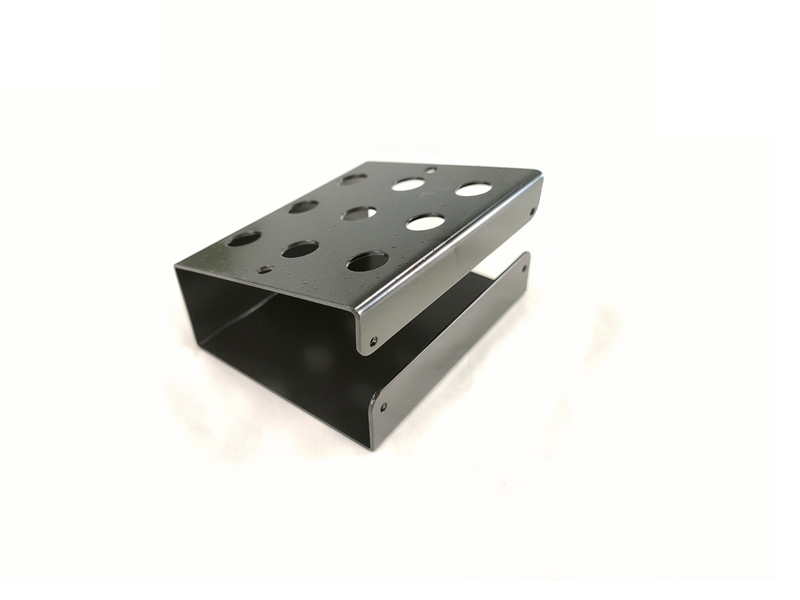

Metal Stamping processing factory production is the use of presses and molds to apply external force to plates, strips, pipes and profiles to cause plastic deformation or separation, so as to obtain the desired shape and size of the workpiece. This is stamping processing, the three indispensable things in stamping processing are metal materials, molds and presses. VMH Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping Processing, Hardware Stamping Processing, Hardware Processing, CNC

According to the deformation characteristics of the material, the stamping process can be divided into two categories, separation and plastic deformation. Separation process means: under the action of external force, the stress of the deformed part exceeds the strength limit of the metal material itself. Plastic deformation of metal stamping refers to: under the action of external force, the stress of the deformed part exceeds the yield limit of the material itself, but when the strength limit is not reached, only plastic deformation occurs to obtain a certain shape and size. In stamping processing, stamping deformation can also be divided into five types: three-dimensional pressing, bending, calendering, forming, and punching.  Metal stamping processing three-dimensional pressing deformation: It is to redistribute the volume and transfer the metal material to a certain extent to change the shape or height thickness of the blank. Bending deformation: It is to deform the flat material into a curved part, so that the shape of the curved part can be further changed. There are bends, curling twists, etc. Calendering deformation: It is to punch the flat blank into the desired hollow part, and the size of the hollow part can also be further changed. Forming deformation: It is to use local deformation of various properties to change the shape of the part or blank. Belonging to forming deformation are undulation forming, flanging, necking, convex belly, rounding, and shaping. Punching deformation: It is not closed or not closed to separate the part of the metal material from another part. This type of method includes blanking, punching, trimming, cutting, cutting, incision, etc. EMAR Hardware [] is a private enterprise specializing in the design and manufacture of various molds and fixtures such as hardware stamping, precision sheet metal parts, CNC processing and precision hardware molds. More hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping processing, hardware processing, CNC lathe processing Please inquire!

Metal stamping processing three-dimensional pressing deformation: It is to redistribute the volume and transfer the metal material to a certain extent to change the shape or height thickness of the blank. Bending deformation: It is to deform the flat material into a curved part, so that the shape of the curved part can be further changed. There are bends, curling twists, etc. Calendering deformation: It is to punch the flat blank into the desired hollow part, and the size of the hollow part can also be further changed. Forming deformation: It is to use local deformation of various properties to change the shape of the part or blank. Belonging to forming deformation are undulation forming, flanging, necking, convex belly, rounding, and shaping. Punching deformation: It is not closed or not closed to separate the part of the metal material from another part. This type of method includes blanking, punching, trimming, cutting, cutting, incision, etc. EMAR Hardware [] is a private enterprise specializing in the design and manufacture of various molds and fixtures such as hardware stamping, precision sheet metal parts, CNC processing and precision hardware molds. More hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping processing, hardware processing, CNC lathe processing Please inquire!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque