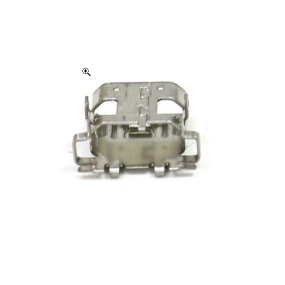

In July 2020, the price of raw materials is now flying up by helicopter, and we are under a lot of pressure when laser cutting and processing, which affects the already bad economic environment. Many processing and manufacturing enterprises have begun to use laser cutting and stamping, and flat stamping parts can be replaced by laser cutting process, because it is really fast enough and cheap enough, saving the time of mold opening and mold testing, and the important processing fee is cheap enough. Furniture factories, jewelry factories, and bag factories have all begun to use laser cutting to process copper parts, aluminum parts, and stainless steel parts in batches? Two German TRUMPF 8000W optical fibers receive orders, which are surprisingly fast and stable in quality.

Choosing a laser cutting processing manufacturer requires strength, good product quality, fast delivery, and low unit price to be king!

Laser cutting processing manufacturers need to provide high-quality products and services. Only by mastering high-precision product manufacturing capabilities can enterprises make price decisions. How to improve product quality requires high-quality production equipment and high-precision manufacturing processes. We are willing to become a high-precision laser cutting processing factory in the manufacturing industry. We have sufficient R & D and production testing capabilities to ensure the high-precision and reliable performance of each set of laser cutting parts.

Quality is the bedrock of an enterprise‘s development. The long-term development of a sheet metal laser processing plant depends on the business operator‘s pursuit of quality. We have always pursued high-quality products, using product quality to cope with the white-hot competition in the market, and using better quality to serve our customers.

Quality is the bedrock of an enterprise‘s development. The long-term development of a sheet metal laser processing plant depends on the business operator‘s pursuit of quality. We have always pursued high-quality products, using product quality to cope with the white-hot competition in the market, and using better quality to serve our customers.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque