Sheet Metal Processing method

1. Blanking method. Blanking is to cut thick materials into bad materials as needed. There are many ways to cut sheet metal. According to the type and working principle of the machine tool, it can be divided into shearing, milling, punching, oxygen cutting and laser cutting. Our company mainly uses shearing, punching and laser cutting.

1.1 Shearing, mainly using a shearing machine to cut the sheet metal with a straight edge, requires to ensure the straightness and parallelism of the shearing surface. And minimize the distortion of the sheet.

1.2 Punching and blanking mainly uses numerical control punching machine or ordinary punching machine and blanking die for blanking.

1.3 Laser cutting uses laser cutting equipment to continuously cut sheets, which is characterized by high efficiency and high precision.

2. Sheet metal processing manual forming

With the continuous development of technological progress in production, the vast majority of the forming process is completed on the machine. Manual methods are often used as supplementary processing or finishing work. However, in the case of single-piece production, or some parts with complex shapes, manual operation and processing are still inseparable. Manual forming is mainly completed by using some simple tire shapes, molds and various fixtures. Manual forming mainly takes the following methods: bending, edge setting, edge closing, edge pulling, arching, hemming, and sewing correction.

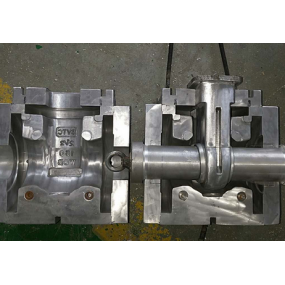

3. Sheet metal processing tool mold forming

Tool and die forming is the use of punching machines, folding machines and various molds to complete the forming of sheet metal. It can be divided into: bending, drawing, local molding and flanging, shrinking, necking, flaring and bulging, forming, bending forming, spinning and leveling. Our company mainly uses bending (bending), leveling or forming and other processes.

Bending (bending) is one of the main methods of sheet metal processing.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque