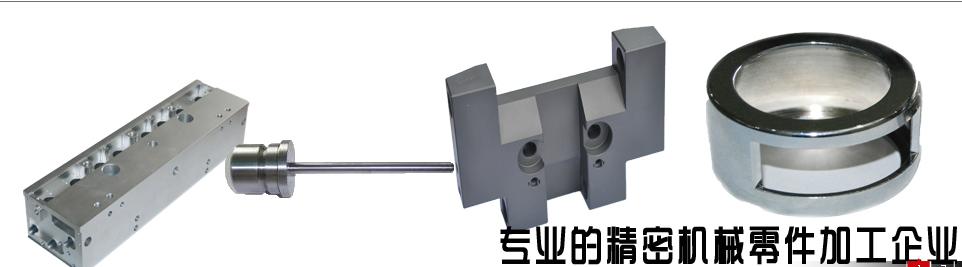

Nowadays, precision mold parts have become the favorite of many customers due to their obvious advantages such as high added value, long service life, and wide application range. Although precision mold parts have been well known by most people, many people are not very clear about its processing process. Let‘s listen to the explanation of Adeli Electromechanical Co., Ltd.

The mold processing process specification is one of the process documents that specify the part mold processing process and operation method. It is to write the more reasonable process and operation method into the process document in the prescribed form under the specific production conditions, and use it to guide production after approval. The mold processing process specification generally includes the following contents: the process route of the workpiece processing, the specific content of each process and the equipment and process equipment used, the inspection items and inspection methods of the workpiece, the cutting dosage, the time quota, etc.

The mold processing process specification is one of the process documents that specify the part mold processing process and operation method. It is to write the more reasonable process and operation method into the process document in the prescribed form under the specific production conditions, and use it to guide production after approval. The mold processing process specification generally includes the following contents: the process route of the workpiece processing, the specific content of each process and the equipment and process equipment used, the inspection items and inspection methods of the workpiece, the cutting dosage, the time quota, etc.

The precision mold parts processing process is based on the process, changing the shape, size, relative position and nature of the production object, etc., to make it a finished product or work in progress. It is a detailed description of each step and each process. For example, as mentioned above, rough machining may include rough manufacturing, grinding, etc. Finishing may be divided into cars, fitters, milling machines, etc. Each step requires detailed data, such as how much roughness to achieve and how much tolerance to achieve.

Technicians determine the process to be used according to the quantity of products, equipment conditions and the quality of workers, and write the relevant content into a process document, which is called a process specification. This is more targeted. Each factory may be different because the actual situation is different.

Overall, the process flow is the program, the processing technology is the detailed parameters of each step, and the process specification is a specific processing technology written by a factory according to the actual situation.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque