Numerical control precision Sheet Metal Processing is well known, but everyone here says that numerical control sheet metal processing is not developed, not only is it not, but it is not developed by everyone. Naturally, everyone also has this kind of work ability, only some people are one step ahead of everyone. The three levels of punch automation in sheet metal automation technology production and processing are briefly described. Stainless steel sheet metal is a production process, and sheet metal has not been fully defined so far. According to a definition in an overseas publication, it can be defined as: Sheet metal is a comprehensive cold drawing processing process for sheet metal.

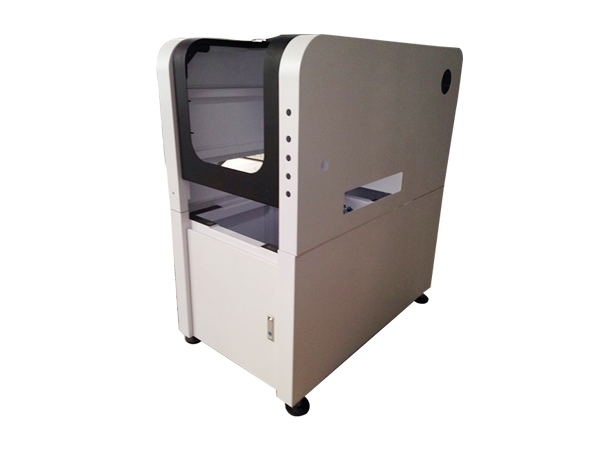

Numerical control sheet metal All or most processes use numerical control machinery, such as numerical control machine tools, numerical control laser cutting machines, numerical control shearing machines, etc. to carry out sheet metal commodity production and manufacturing. Can achieve high commodity precision and reduce Product Research & Development. Can immediately go from drawing to electronic production of commodities. Suitable for small batch production of various types of intelligent production. But some people lead it is not a drawback, just everyone is passive everywhere, so everyone is lagging behind in Europe, America and other countries. We know that industrial production and manufacturing is the strength of Germany, and the facilities of Product Research & Development are of course the strength of these people and so far, the vast majority of the facilities introduced in our country are produced in Germany. And numerical control sheet metal machinery and equipment is also, naturally, small and medium-sized, we can produce it ourselves, so the mouth can not be considered.

The question is, everyone says that numerical control sheet metal, but what are the application areas of numerical control sheet metal?

Numerical control sheet metal processing is a precision production and processing method, which can cut almost all raw materials, including two-dimensional cutting or three-dimensional cutting of thin metal sheets. In the automobile manufacturing industry, the cutting technology of indoor space straight lines such as car roof windows has long been widely used. Volkswagen of Germany uses a laser generator with an output power of 500W to cut complex body panels and various inclined parts. In the aerospace industry, numerical control sheet metal technology is suitable for cutting special aviation materials, such as titanium alloys, aluminum alloy profiles, nickel-based alloys, nickel-iron alloys, stainless steel plates, beryllium oxide, composite materials, plastics, porcelain and quartz stone. The aerospace parts processed by numerical control sheet metal include automobile engine flame barrel, titanium alloy thin-walled casing, airport structure, titanium alloy skin, aircraft wing long truss, automobile tail wall plate, helicopter main rotor aircraft, spacecraft porcelain insulation tile, etc.

At this stage, the key to precision sheet metal processing is to cut metal materials that are more commonly used at this stage, such as stainless steel plates, iron plates, aluminum alloy plates, etc., because this is a common product chemical substance in our daily life, and numerical control sheet metal is not What metal materials can be cut, precious metals and other rare metals are his shortcomings, and it can only be seen when dealing with this metal material.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque