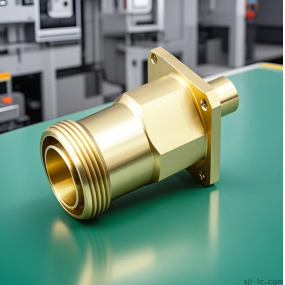

Hardware stamping parts are widely used in daily life, and a large portion of metal parts are processed by stamping. Today, let's learn about the process characteristics of hardware stamping parts.

Hardware stamping parts

Hardware: Parts produced and processed from steel or some rare metals. The production and processing methods include cold/hot stamping, extrusion forming, extrusion forming, welding, drilling, and other processing techniques, which are widely defined.

Stamped parts: commonly used in hardware processing, refer to metal products made of materials such as steel or rare metals that pass through molds and are processed by a press machine under machine pressure to form a specific shape under indoor temperature standards.

Hardware stamping parts are widely used in various industries in people's daily lives, including electronic components, automotive parts, and building decoration materials. The commonly used stamping parts refer to cold stamped parts. For example, if a stainless steel plate wants to be turned into a disc, a set of molds must be designed first. The working surface of the mold is like a disc. Pressing the stainless steel plate with the mold will turn it into the disc you want. This is cold stamping, which means immediately using the mold to stamp the hardware material.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque