In 2020, the market was sluggish, and many large processing manufacturers closed down, causing many suppliers to have difficulties in operation. This kind of thing happened repeatedly, which made many laser cutting factories operate more conservatively, encountering customer orders that were not prosperous enough in the industry and did not pay in time. Selective cooperation and transactions. It is precisely because of the conservative cooperation of the entire industry that many buyers cannot find suitable supply factories, so they have to change the payment terms, reduce the payment pressure of production and processing enterprises, and propose a cooperation model of cash transactions.

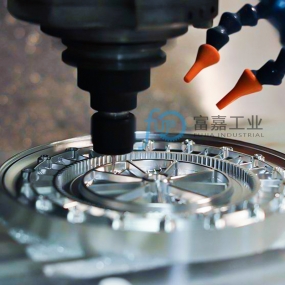

EMAR laser cutting processing, 20MM stainless steel plate can also be cut and formed efficiently, with amazing speed!

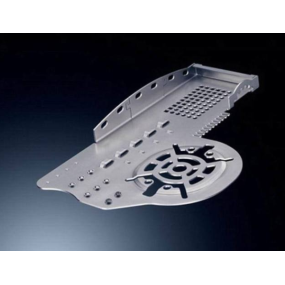

laser cutting is mainly used in chassis, cabinets and aluminum plate cutting and copper plate cutting. When a product is finalized, the dosage is very large. Laser cutting requires several tons of material for a single order. If the customer has a account period, the financial pressure of the manufacturer with high supply is very large. If there is a problem of capital withdrawal, the enterprise is prone to the risk of capital chain rupture. Faced with the monthly account or account period order of the customer, the enterprise feels pressure, but in order to survive and develop, it can only accept it silently, and the pain can only be borne by itself.

laser cutting is mainly used in chassis, cabinets and aluminum plate cutting and copper plate cutting. When a product is finalized, the dosage is very large. Laser cutting requires several tons of material for a single order. If the customer has a account period, the financial pressure of the manufacturer with high supply is very large. If there is a problem of capital withdrawal, the enterprise is prone to the risk of capital chain rupture. Faced with the monthly account or account period order of the customer, the enterprise feels pressure, but in order to survive and develop, it can only accept it silently, and the pain can only be borne by itself.

In fact, any cooperation is mutual and win-win. Just because you are the demand side and a well-known enterprise, you cannot bully the manufacturer, delay the payment period, and let the supplier bear the financial pressure and risk. This is unfair. The development of any enterprise requires the support of qualified and responsible suppliers. Only when suppliers can produce with peace of mind and control the quality can they deliver qualified products, so that both parties can win.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque