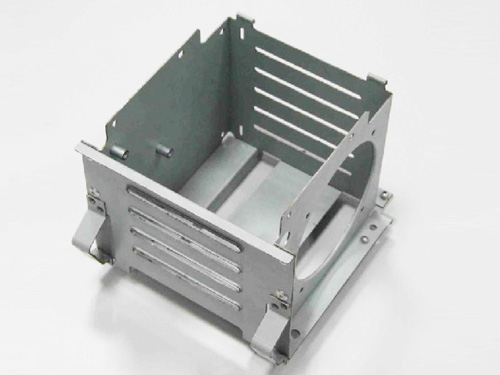

Sheet Metal Processing explains that sheet metal chassis cabinets will experience some later problems after production, such as resonance during the working process and dust in the air, which will cause certain damage to sheet metal chassis cabinets. So how can these problems be improved and avoided?

Sheet metal processing first look at how to avoid resonance in sheet metal chassis cabinets? Sheet metal chassis cabinets will generate certain vibrations during the working process, and long-term resonance will cause certain damage to machinery and equipment. So in the face of this vibration, it is necessary to install shock absorbers during sheet metal processing, and there is almost no resonance amplification phenomenon in the range of 10~ 2000Hz after installation. Although there are irregular spikes around 200Hz, sheet metal chassis cabinets have resonance amplification, but the time is very short, the transmission rate is quickly reduced, and the impact on the cabinet is not significant. For chassis cabinets, cracks and other phenomena need to be detected after leaving the factory, and the connection should not be loose. Through strengthening the design of the cabinet, selecting a reasonable vibration isolation system, and then conducting tests and verification, the sheet metal chassis cabinet can meet the requirements of the airborne environment. With the research and application of new sheet metal processing vibration isolation technology, as well as the continuous improvement of dynamic testing technology and the improvement of vibration analysis level, the vibration isolation design method will be more abundant and perfect.

No matter what kind of chassis sheet metal processing is exposed to the air for a long time, it will be contaminated with dust or oxidized, and it will become less bright. Do we have measures to deal with this situation of sheet metal chassis? Or how should we maintain the sheet metal chassis? The easiest way to maintain a sheet metal chassis is to clean it.

1. First, the surface of the sheet metal chassis needs to be rinsed with water to remove the dirt on its surface.

2. Then add soap, liquid detergent or 5% ammonia solution for wiping.

3. Rinse carefully with water again.

4. Finally, we dry the remaining water stains on the surface of the chassis and cabinet. During the drying process, we need to wipe in the same direction in order to make it cleaner. After the wiping is completed, we can let the surface dry naturally.

5. Although it is irreversible for a sheet metal chassis to age, by cleaning it regularly, we can delay this "aging" and keep the sheet metal chassis clean, which is also conducive to improving its working condition. If the sheet metal chassis cabinet is properly maintained, it can prolong its service life and reduce production costs.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque