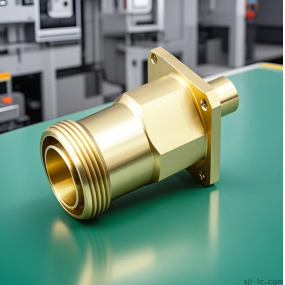

Equipment chassis rack processing has extremely high specifications, the components are matched with each other, the dimensional precision can reach the millimeter level, such as the following, must meet the standards:

The bottom surface and other sides of the chassis should maintain a 1mm flatness.

2. The perpendicularity of the surrounding surfaces of the chassis should be accurate to 1mm relative to the bottom surface.

3. After loading the panel into the chassis, it should be able to maintain the vertical end in line with the size of the chassis, and make its side and bottom surfaces 0.5mm perpendicular to the bottom surface of the chassis.

4. The assembly of the chassis shell and other components must be taken advantage of, and there should be no loosening or floating phenomenon in the connection; and the insertion and extraction of each plug-in should be able to proceed smoothly without hindrance or stagnation.

5. The chassis shell should always be smooth and flat, free from scratches or bumps.

The extensive use of sheet metal chassis is mainly due to its excellent material characteristics. To sum up, it can be roughly divided into the following aspects:

1. The sheet metal chassis shell has good electrical conductivity, and with a little use, it can exert the effect of electromagnetic shielding, effectively eliminate the influence of external electromagnetic on its interior, and achieve good protection.

2. The overall high strength and light weight of the chassis ensure its robustness, can withstand certain external shocks, is not easy to deform, and has high safety performance; on the other hand, it makes it suitable for handling and installation

It is more convenient to use and has certain advantages in promoting applications.

3. The production cost of sheet metal chassis is low, and it can be mass-produced, which not only enhances its economic cost-effectiveness, but also facilitates the mass production of chassis, thus gaining more applications.

4. High-precision dimensions, due to the use of Sheet Metal Processing technology, the precision of its components in terms of size is at the millimeter level, which only greatly enhances the safety and stability of its use.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque