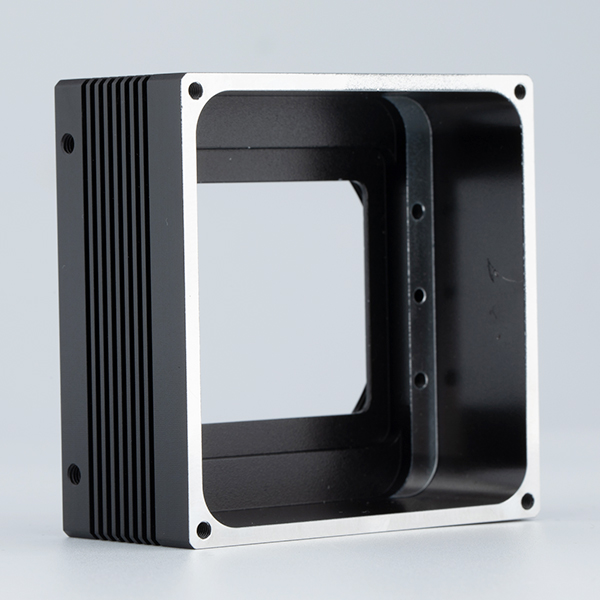

1. Strength and rigidity Sufficient strength: numerical control aluminum alloy parts The main numerical control tool needs to withstand large cutting force and vibration during the working process, so the aluminum alloy material needs to have enough strength to ensure the stability and life of the tool. This strength requirement ensures that the parts are not easily deformed or damaged during processing and use. Good rigidity: Materials with good rigidity can better resist deformation during cutting and improve machining accuracy and stability.  2. Lightweight aluminum alloy is a lightweight material. Compared with traditional materials such as steel, aluminum alloy parts can significantly reduce weight. This helps to reduce machine tool load, improve cutting efficiency, and reduce energy consumption. 3. Thermal conductivity numerical control tools will generate a lot of heat during high-speed cutting. If the thermal conductivity of the material is not good, it is easy to cause the tool to overheat, thus affecting the cutting quality and tool life. Aluminum alloy has good thermal conductivity, which can effectively dissipate heat and maintain the stability of the tool. 4. Corrosion resistance numerical control aluminum alloy parts often need to be in contact with corrosive media such as cutting fluid, so the material needs to have certain corrosion resistance to prolong the service life of the parts. Corrosion resistance of aluminum alloy is usually good, but in some special environments, additional surface treatment may be required to improve its corrosion resistance. 5. Machinability aluminum alloy is easy to machine and can meet the high precision and high efficiency requirements of numerical control machining. Its good cutting performance helps to reduce processing time and cost and improve production efficiency. 6. Selection of Alloy Elements The aluminum alloy used for CNC Machining is not pure aluminum, but an alloy containing a small amount of alloying elements. By adjusting the content of alloying elements, aluminum alloy materials with different properties can be manufactured. For example, the addition of elements such as silicon, manganese, magnesium, copper and zinc can improve the strength, hardness, corrosion resistance and other properties of aluminum alloys. 7. Other specific requirements According to different applications and needs, numerical control of aluminum alloy parts production may also need to meet other specific requirements, such as high temperature resistance, wear resistance, fatigue resistance, etc. These requirements may need to be customized and selected according to specific situations.

2. Lightweight aluminum alloy is a lightweight material. Compared with traditional materials such as steel, aluminum alloy parts can significantly reduce weight. This helps to reduce machine tool load, improve cutting efficiency, and reduce energy consumption. 3. Thermal conductivity numerical control tools will generate a lot of heat during high-speed cutting. If the thermal conductivity of the material is not good, it is easy to cause the tool to overheat, thus affecting the cutting quality and tool life. Aluminum alloy has good thermal conductivity, which can effectively dissipate heat and maintain the stability of the tool. 4. Corrosion resistance numerical control aluminum alloy parts often need to be in contact with corrosive media such as cutting fluid, so the material needs to have certain corrosion resistance to prolong the service life of the parts. Corrosion resistance of aluminum alloy is usually good, but in some special environments, additional surface treatment may be required to improve its corrosion resistance. 5. Machinability aluminum alloy is easy to machine and can meet the high precision and high efficiency requirements of numerical control machining. Its good cutting performance helps to reduce processing time and cost and improve production efficiency. 6. Selection of Alloy Elements The aluminum alloy used for CNC Machining is not pure aluminum, but an alloy containing a small amount of alloying elements. By adjusting the content of alloying elements, aluminum alloy materials with different properties can be manufactured. For example, the addition of elements such as silicon, manganese, magnesium, copper and zinc can improve the strength, hardness, corrosion resistance and other properties of aluminum alloys. 7. Other specific requirements According to different applications and needs, numerical control of aluminum alloy parts production may also need to meet other specific requirements, such as high temperature resistance, wear resistance, fatigue resistance, etc. These requirements may need to be customized and selected according to specific situations.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque