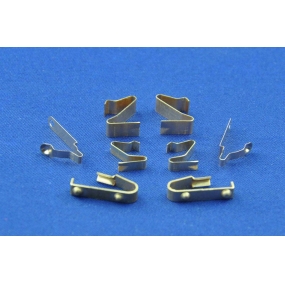

The process of Sheet Metal Processing is very complicated, so the price of sheet metal processing should not be too low. Analyze which parts are included in the price of sheet metal processing? The price composition of sheet metal processing: raw material cost, the net material cost of the metal sheet required for sheet metal parts, according to the maximum length and width of the part drawing thickness density, material cost = material weight material unit price. Hardware parts cost, according to the requirements of the product drawings, the procurement cost of locks, hinges, handles, nameplates, rivets or fastening standard parts and other accessories. Processing cost, the cost required for the sheet metal processing process. Processing cost is usually composed of the depreciation and amortization of the equipment used in each station, the cost of labor hours and the auxiliary materials necessary for processing. There are many workstations for sheet metal processing, including blanking, forming, surface treatment, packaging, transportation, management, etc., which all need to be cost-calculated. In addition, each process of sheet metal processing requires some special mechanical equipment, which also requires high costs. Sheet metal processing requires many processes, including shearing, bending, bending, forming, welding, riveting, etc. However, each process requires different sheet metal processing equipment. 1. Welding equipment: mainly for butt welding machines and argon arc welding machines. 2. Cutting equipment: including grinding wheel cutting machines, air plasma cutting machines, and angle grinders. 3. Processing machinery and equipment: bending machines, cutting machines, rolling machines and punches, etc. 4. Other equipment: air compressors, grinders, and some painting equipment.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque