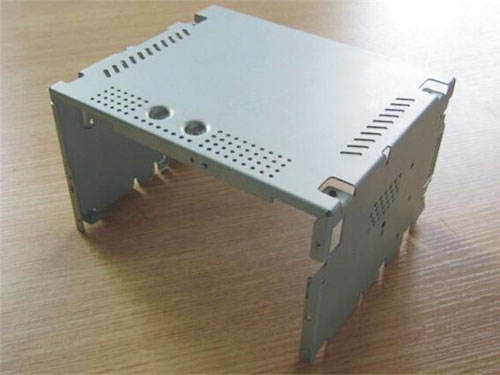

Analysis of Errors in Machining Equipment Chassis and Rack

There is no perfect thing in the world, and even if there is one, it is flawed. Although equipment chassis rack processing has been recognized by a wide range of users, it also has some planning shortcomings.

1. Disposable baffle, there is an appropriate part of the use of a one-time punch baffle, on the chassis cabinet products of this plan, every time the equipment is a new PCI card, the main board has to be removed, and the equipment is properly troublesome.

2. Non-removable front panel. A few chassis cabinets are fixed to the front frame of the chassis cabinet with plastic rivets. Once the power switch is stuck or the indicator light falls, the panel needs to be removed for repair. This non-removable front panel chassis cabinet is a serious problem.

3. Misunderstandings in the planning of electric fans. Electric fans are used for heat dissipation, not the more the better. They must have a suitable orientation and form an excellent air duct to effectively dissipate heat.

4. The question of the cassette structure, the biggest question of this kind of plan is that it requires a strict comparison of the standard tolerances of the accessories, unlike the screw structure, which allows the accessories to have a certain "dislocation". If it is forcibly installed, it will bring the risk of deformation of the accessories. If it is often disassembled, it will definitely affect the overall stability.

Equipment chassis rack processing maintenance skills are:

Equipment chassis rack processing maintenance skills are:

When we use Sheet Metal Processing, if it has a weld, we will first pickle it and then phosphate it. After we use it for a period of time, there will be rust water flowing out of it, so we know that there is corrosion in it, but how should we solve it?

When we pickle, the acid is not fully neutralized, so when we phosphate, there will be rust. We can also use strong acid for pickling, which is actually a strongly alkaline degreasing work. Rinse off the residual medicine, and then dry it, so that white things will appear in the cracks. After a while, these white substances will come into contact with the air and react. Usually these problems appear in March-November, so we have to pay special attention.

If you want to prevent corrosion and rust in sheet metal processing, then our degreasing medium should use weakly alkaline substances, and there should be no alkali components. When pickling, we can use sulfuric acid, and the pickling time should not be too long. If it is phosphoric acid, it is better. After we pickle, we need to use sodium carbonate for neutralization. When our tasks are completed, then we will clean it up. Of course, we usually wash it with water. If you think what the editor said is not in place, you can also tell us your opinion.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque