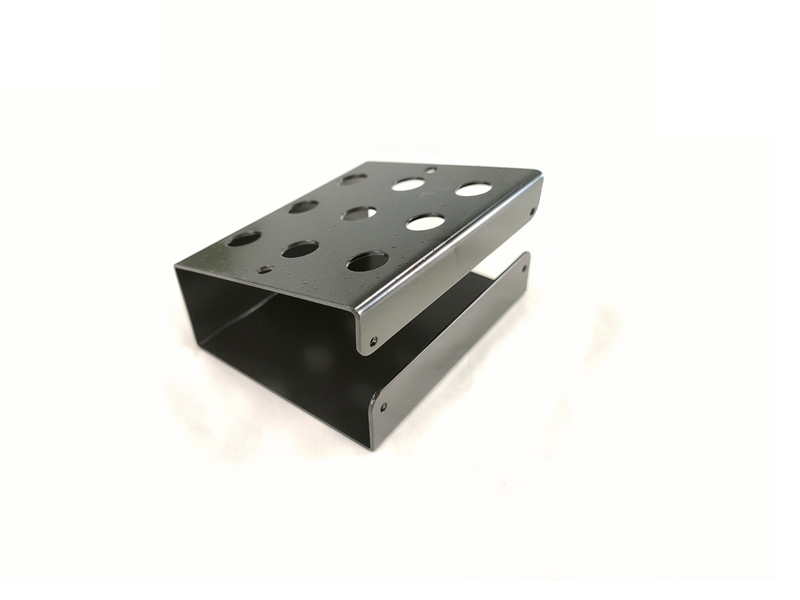

Hardware factories will encounter some processing problems during the stamping production process, such as the uneven surface of the stamping parts. So when the surface of the stamping parts is uneven, how should the stamping parts processing factory deal with it? The following hardware stamping parts editor will take you to understand. YuG Hardware Factory, Hardware Products, Metal Products, Precision Sheet Metal, Hardware Processing, Sheet Metal Factory, Metal Stamping, Hardware Stamping, CNC

To overcome the uneven surface of the stamping parts, the following methods can be taken: 1. Regular inspection and adjustment of the stamping die: The stamping die needs regular inspection and maintenance to reduce the problem of the concave and convex of the stamping parts. The general practice is to use the test product to check the bonding scratches of the hemming strip and the condition of the processing surface (cavity arc, die base arc).  2. Moderate manipulator speed: For the production and manufacture of fully automatic stamping dies in hardware factories, when the punch is in the lower die part and the speed of the manipulator is rapid, the burr will fall on the upper end of the punch, causing concave and convex problems. In order to prevent such problems, we can do the discharge experiment of the stamping parts before the production and manufacture, and effectively set the speed and discharge angle of the manipulator, so that it is not easy to encounter the stamping parts and the lower die. 3. Check the cut-off surface: When disconnecting the pipe material, the wear and damage of the cut-off die will cause many fine fans to adhere to the knife edge. Therefore, it is necessary to check the double cut-off surface in the material area or the stamping die line before the production and manufacture of the stamping die, and then clean the material to remove the rough edge. 4. Inspection of plate cleaning equipment: Before the production and manufacture of the stamping die in the hardware factory, it is necessary to check the refurbishment and cleaning installation regularly, and clean the raw materials more reasonably. This is also very important, and it is also necessary to pay attention to the quality of the roller gap and cleaning oil. This information is provided by EMAR hardware manufacturers, and more hardware factories, hardware products, metal products, precision sheet metal, metal processing, sheet metal factories, metal stamping, metal stamping, metal processing, CNC lathe processing, and other information. We warmly welcome people from all walks of life to visit our factory for negotiation and guidance. We will serve you wholeheartedly.

2. Moderate manipulator speed: For the production and manufacture of fully automatic stamping dies in hardware factories, when the punch is in the lower die part and the speed of the manipulator is rapid, the burr will fall on the upper end of the punch, causing concave and convex problems. In order to prevent such problems, we can do the discharge experiment of the stamping parts before the production and manufacture, and effectively set the speed and discharge angle of the manipulator, so that it is not easy to encounter the stamping parts and the lower die. 3. Check the cut-off surface: When disconnecting the pipe material, the wear and damage of the cut-off die will cause many fine fans to adhere to the knife edge. Therefore, it is necessary to check the double cut-off surface in the material area or the stamping die line before the production and manufacture of the stamping die, and then clean the material to remove the rough edge. 4. Inspection of plate cleaning equipment: Before the production and manufacture of the stamping die in the hardware factory, it is necessary to check the refurbishment and cleaning installation regularly, and clean the raw materials more reasonably. This is also very important, and it is also necessary to pay attention to the quality of the roller gap and cleaning oil. This information is provided by EMAR hardware manufacturers, and more hardware factories, hardware products, metal products, precision sheet metal, metal processing, sheet metal factories, metal stamping, metal stamping, metal processing, CNC lathe processing, and other information. We warmly welcome people from all walks of life to visit our factory for negotiation and guidance. We will serve you wholeheartedly.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque