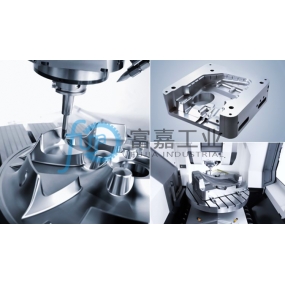

City EMAR Hardware Products Co., Ltd. has high-end laser cutting equipment - German pass block 4000W cutting machine, we are constantly innovating technology only to help customers better laser cutting processing production problems and improve efficiency! Start-up clock in cutting S136, fine groove rough, in the German TRUMPF high-power fiber optic machine with high-pressure nitrogen fast cutting efficiency and accuracy are particularly advantageous, it is beautiful and positive processing costs, you deserve it, stable cutting of copper and aluminum special materials, 1-25 centimeters stainless steel plate, ready to turn on for your service.

The reason why laser cutting processing has been developed in recent years is that the traditional Sheet Metal Processing method manufacturing enterprises need to pay a lot of labor, which has become a burden for enterprises when the labor cost remains high. In this case, if high-tech laser cutting can replace stamping and forming, it will solve the big problem of customers and will inevitably be sought after by enterprises.

In terms of mechanical equipment processing and manufacturing, each of their products requires a sheet metal shell and copper and aluminum bars. The traditional production method has low speed, high error rate, and inconsistent quality. The use of German TRUMPF laser cutting equipment can efficiently solve the problem of cutting copper and aluminum plates in enterprises, and improve the processing and manufacturing level of products.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque