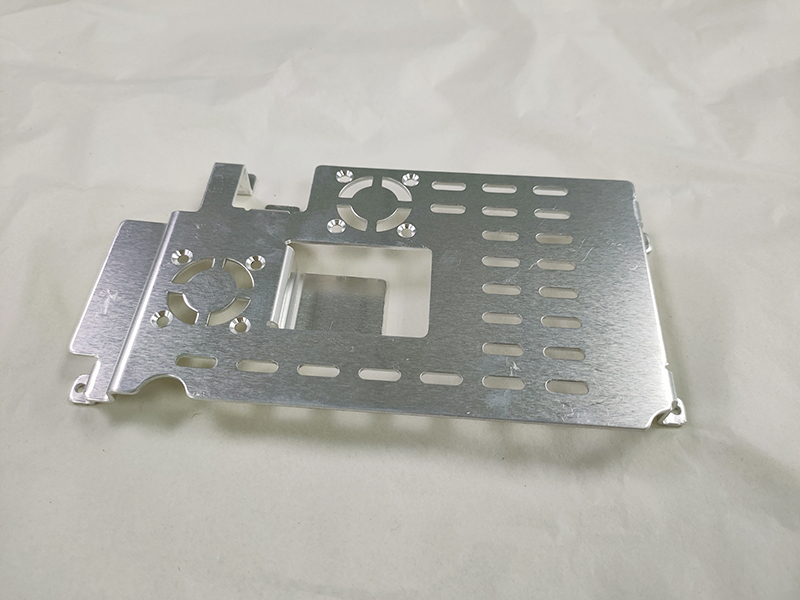

Metal Stamping is a common metal processing parts in the metal material processing and machinery and equipment manufacturing industries, and its applications are also very wide, including automotive, electronics, medical equipment and other precision industries. Stamping dies, stamping machinery and equipment, and stamping raw materials are the three elements that make up the processing. Let‘s talk about the processing characteristics of metal stamping parts: epL hardware factory, metal products, metal products, precision sheet metal, hardware processing, sheet metal factory, metal stamping, metal stamping, metal processing, CNC

1. Stamping generally has no cutting edge, consumes less raw materials, and does not require other heating equipment, so it is a processing method that not only counts materials, but also is environmentally friendly and energy-saving, and the cost of stamping parts is low.  2. In the case of metal stamping processing, because the die ensures the precision of the specifications and appearance design of the stamping parts, and it is not easy to destroy the process performance of the stamping parts, the service life of the die is relatively long! 3. Metal stamping processing has high processing and production efficiency, and the actual operation is simple and convenient, making it very easy to complete automation technology and mechanical automation. The reason for this is that stamping relies on stamping machine equipment and stamping dies for processing. Relative to the general press stroke arrangement frequency, it can generally be done dozens of times per minute, while for high-speed working pressure, it can reach more than a thousand punches per minute, and each stamping stroke can produce a stamping part, with high production efficiency. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factories, metal stamping processing, hardware stamping, hardware processing, CNC lathe processing and other information. We warmly welcome people from all walks of life to visit our factory for negotiation and guidance. We will serve you wholeheartedly.

2. In the case of metal stamping processing, because the die ensures the precision of the specifications and appearance design of the stamping parts, and it is not easy to destroy the process performance of the stamping parts, the service life of the die is relatively long! 3. Metal stamping processing has high processing and production efficiency, and the actual operation is simple and convenient, making it very easy to complete automation technology and mechanical automation. The reason for this is that stamping relies on stamping machine equipment and stamping dies for processing. Relative to the general press stroke arrangement frequency, it can generally be done dozens of times per minute, while for high-speed working pressure, it can reach more than a thousand punches per minute, and each stamping stroke can produce a stamping part, with high production efficiency. This information is supplied by EMAR hardware manufacturers, more hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factories, metal stamping processing, hardware stamping, hardware processing, CNC lathe processing and other information. We warmly welcome people from all walks of life to visit our factory for negotiation and guidance. We will serve you wholeheartedly.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque