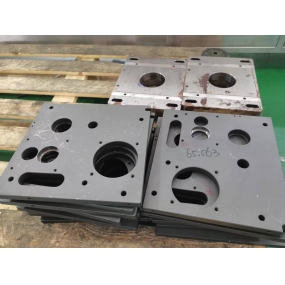

Nowadays, there are many types of processing methods involved in the metal processing industry, and large-scale Sheet Metal Processing is one of the more common processing methods. During processing and production, staff need to learn processing techniques first, so as to ensure the processing quality and processing accuracy of materials.

This processing method involves a lot of content, allowing people to complete cutting and blanking processes during processing. After these processing procedures, the production purpose can be achieved. Staff usually need to pay attention to the parameters and characteristics during processing and production. These are important aspects that cannot be ignored.

Before sheet metal processing, the staff also need to understand the processing range. Generally, during processing operations, materials such as copper products, galvanized sheet, and stainless steel can be selected to complete the processing process. Therefore, this processing method has a wide range and can also meet the processing and production needs of different industries. During processing, people can choose materials flexibly without worrying that the materials do not meet the processing requirements and affect the progress of the production task.

In the process of sheet metal processing, several issues need to be paid attention to. First, the staff should check the material before processing, and unfold the material for processing. The material should be unfolded in the correct way, so that materials can be saved during processing, and processing purposes can also be achieved. During processing, attention should also be paid to the selection of gaps and the hemming effect of materials.

During sheet metal processing, staff should have a good understanding of the production process and processing methods, so that they can better complete the processing tasks and ensure the quality of the workpiece.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque