Shenzhen numerical control turning and milling, how much do you know?

Shenzhen numerical control turning and milling machining is mainly used for the processing of non-rotating parts, especially in the mold manufacturing industry.

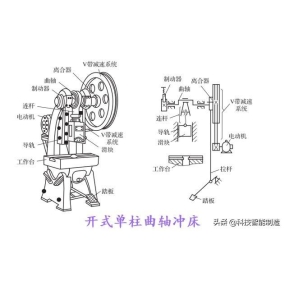

1. Milling machine: a machine tool that uses a milling cutter to mill workpieces. In addition to milling planes, grooves, gear teeth, threads, and spline shafts, milling machines can also process more complex profiles, with higher efficiency than planers. They are widely used in machinery manufacturing and repair departments.

2. Planer: a linear motion machine tool that uses a planer to plane the plane, groove or forming surface of a workpiece. The planer is used for machining, and the tool is relatively simple, but the productivity is low (except for machining long and narrow planes), so it is mainly used for single-piece, small-batch production and machine repair workshops, and is often replaced by milling machines in large-scale production. According to the structure and performance, planers are mainly divided into bull head planers, gantry planers, single-arm planers, and specialized planers (such as edge planers for planing large steel plates, planers for planing punches, and planers for complex-shaped workpieces).

The bullhead planer is named after the ram and tool holder that resemble the bullhead. The planer is installed on the tool holder of the ram for longitudinal reciprocating motion, which is mostly used for cutting various planes and grooves. The gantry planer is named after a gantry frame structure composed of a top beam and a column. The worktable carries the workpiece through the gantry frame for linear reciprocating motion. It is mostly used for machining large planes (especially long and narrow planes), and it is also used for machining grooves or the plane of several medium and small parts at the same time. Large gantry planers are often accompanied by milling heads and grinding heads, so that the workpiece can be installed in one time to complete the work of planing, milling and grinding the surface. The single-arm planer has a single column and a cantilever, and the table reciprocates lengthwise along the bed guide rail, which is mostly used to process workpieces with a large width and do not need to be processed on the entire width.

The cutter or workpiece reciprocates in a straight line, and the workpiece and cutter make an intermittent feed movement perpendicular to the main movement. Commonly used planers are: bull planer, gantry planer and single-arm planer.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque