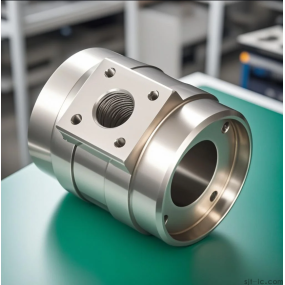

Four processing stages of CNC prototype model making process

When the surface accuracy and roughness requirements of a part are relatively high, it is often impossible to complete the processing in one process, and it is divided into several stages for processing.

When the surface accuracy and roughness requirements of a part are relatively high, it is often impossible to complete the processing in one process, and it is divided into several stages for processing.

1.Four processing stages of the CNC prototype model making process

(1) Roughing stage. Roughing is mainly to remove most of the machining allowance on each surface, so that the shape and size of the blank are close to the finished product. This stage is characterized by the use of high-power machine tools and the selection of larger cutting tools to improve productivity and reduce tool wear as much as possible.

(2) Semi-finishing stage. Semi-finishing is to complete the processing of secondary surfaces and prepare for the finishing of major surfaces.

(3) Finishing stage. Finishing is the process of ensuring that the main surface meets the requirements of the pattern.

(4) Finishing stage. Finishing is a surface that requires high surface roughness and machining accuracy, and requires finishing. This stage generally cannot be used to improve the positional accuracy of parts.

It should be pointed out that the division of the processing stage is based on the entire process of parts processing, and cannot be judged by the processing of a surface or the nature of a certain process. At the same time, in specific applications, it cannot be absolute. For some heavy parts or parts with small margin and low precision, rough finishing of the surface can be completed after one clamping.

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque