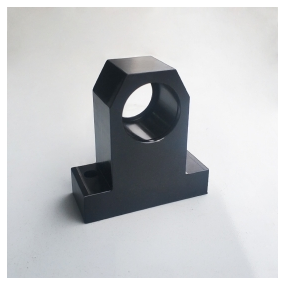

Metal processing EMAR analysis How to improve the quality of precision parts processing? What aspects need to be paid attention to? Let‘s take a look! zK2 hardware factory, hardware products, metal products, precision sheet metal, metal processing, sheet metal factory, metal stamping, metal stamping, metal processing, CNC

First, the staff must have rich experience in machining and excellent technology. Machining must have excellent technology to do well, as we all know that machining is the same fine work. It is a very test of the production process, even if it can be done well, it will take a long time. If you don‘t start well at the beginning, it is easy to give up all your efforts. Second, whether the processing process is standardized and excellent also determines whether the product is of high quality. This is also an indispensable reference point when we use to formulate company rules and regulations. Production and management are bound to require a perfect set of processes, and the hardware processing process is to serve the production of perfect products.  Third, we must pay attention to communication in the production process. Whether it is node time or when there is a problem, we must strengthen communication. Communication between processing plants and equipment manufacturers is an important condition for doing a good job in the processing of automated equipment parts. Processing personnel usually follow the drawings for processing work, but more often, many process areas can be simplified and improved, which can not only reduce costs, but also improve efficiency. Hardware Processing EMAR Hardware [] is a private enterprise specializing in the design and manufacture of various molds and fixtures such as hardware stamping, precision sheet metal parts, CNC Machining and precision hardware molds. More hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factories, metal stamping processing, hardware processing, CNC lathe processing. Please inquire!

Third, we must pay attention to communication in the production process. Whether it is node time or when there is a problem, we must strengthen communication. Communication between processing plants and equipment manufacturers is an important condition for doing a good job in the processing of automated equipment parts. Processing personnel usually follow the drawings for processing work, but more often, many process areas can be simplified and improved, which can not only reduce costs, but also improve efficiency. Hardware Processing EMAR Hardware [] is a private enterprise specializing in the design and manufacture of various molds and fixtures such as hardware stamping, precision sheet metal parts, CNC Machining and precision hardware molds. More hardware factories, hardware products, metal products, precision sheet metal, hardware processing, sheet metal factories, metal stamping processing, hardware processing, CNC lathe processing. Please inquire!

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque