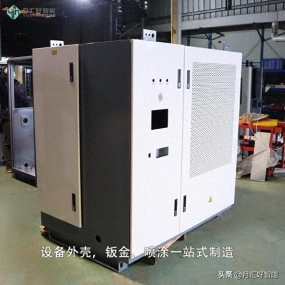

There are many aspects that need to be paid attention to in the spraying process of cabinet Sheet Metal Processing. It is necessary to comprehensively consider various factors to ensure the quality and safety of spraying. In the spraying process of cabinet sheet metal processing, the following aspects need to be paid attention to:  Surface treatment: Impurities such as oil stains and dust on the surface of sheet metal can have a serious impact on the spraying quality, so thorough surface treatment is required. Commonly used surface treatment methods include sanding, chemical treatment, electrophoresis, etc., to ensure that the surface of sheet metal is clean, smooth and free of impurities. Process selection: According to the shape, size, quantity, quality requirements and other factors of sheet metal parts, choose the appropriate spraying process. Different processes have different effects on spraying effect, coating thickness, adhesion, etc., so careful evaluation and selection are required. Environmental control: The spraying environment is crucial to the quality of spraying. Before spraying, it is necessary to ensure that the spraying environment is dry, clean, windless, dust-free, the temperature is suitable, and the constant temperature is maintained. This helps to reduce the defects such as bubbles and impurities in the coating and improve the spraying quality. Spraying quality: The quality of spraying directly affects the appearance and performance of sheet metal parts. In the spraying process, it is necessary to choose high-quality coatings and control the spraying technology, coating thickness, adhesion and other factors. At the same time, attention should be paid to avoid problems such as paint flow, missed spraying, and foaming, and deal with these problems in a timely manner. Painting treatment: After the spraying is completed, it is necessary to carry out paint treatment. The temperature and time of baking paint need to be determined according to the type and thickness of the paint to ensure that the coating is fully dried and cured, and to improve the hardness and wear resistance of the coating. Safety protection: Harmful gases and dust may be generated during the spraying process, posing a threat to the health of the operator. Therefore, good ventilation facilities should be set up in the spraying operation area, and necessary protective equipment should be worn, such as gas masks, gloves, etc.

Surface treatment: Impurities such as oil stains and dust on the surface of sheet metal can have a serious impact on the spraying quality, so thorough surface treatment is required. Commonly used surface treatment methods include sanding, chemical treatment, electrophoresis, etc., to ensure that the surface of sheet metal is clean, smooth and free of impurities. Process selection: According to the shape, size, quantity, quality requirements and other factors of sheet metal parts, choose the appropriate spraying process. Different processes have different effects on spraying effect, coating thickness, adhesion, etc., so careful evaluation and selection are required. Environmental control: The spraying environment is crucial to the quality of spraying. Before spraying, it is necessary to ensure that the spraying environment is dry, clean, windless, dust-free, the temperature is suitable, and the constant temperature is maintained. This helps to reduce the defects such as bubbles and impurities in the coating and improve the spraying quality. Spraying quality: The quality of spraying directly affects the appearance and performance of sheet metal parts. In the spraying process, it is necessary to choose high-quality coatings and control the spraying technology, coating thickness, adhesion and other factors. At the same time, attention should be paid to avoid problems such as paint flow, missed spraying, and foaming, and deal with these problems in a timely manner. Painting treatment: After the spraying is completed, it is necessary to carry out paint treatment. The temperature and time of baking paint need to be determined according to the type and thickness of the paint to ensure that the coating is fully dried and cured, and to improve the hardness and wear resistance of the coating. Safety protection: Harmful gases and dust may be generated during the spraying process, posing a threat to the health of the operator. Therefore, good ventilation facilities should be set up in the spraying operation area, and necessary protective equipment should be worn, such as gas masks, gloves, etc.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque