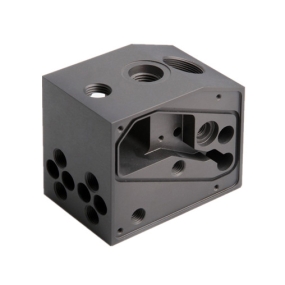

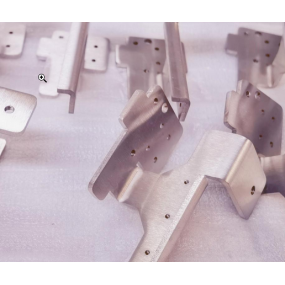

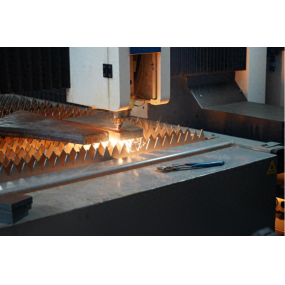

A professional Sheet Metal Processing manufacturer, providing customers with a large number of product parts processing, chassis and cabinet processing, etc. The types of sheet metal processing parts can be divided into three types: First: Parts with aerodynamic shape: including the skin of the aircraft fuselage, wings, tail and intake port, the skin of the missile body, rudder surface, the combustion chamber and nozzle of the rocket engine, etc. Second, skeleton parts: including longitudinal, transverse and oblique components, such as beams, trusses, partitions, wing ribs, etc. Third, interior parts: including fuel, control, communication and other systems, as well as various sheet metal processing parts in life service facilities, such as fuel tanks, various catheters, brackets, seats, etc. The basic requirements of sheet metal processing parts: parts with aerodynamic shape have accurate, smooth and streamlined curved surface shape; skeleton parts can maintain the highest structural efficiency with minimum self-weight; all sheet metal processing parts have the required strength, stiffness and physical and chemical properties such as fatigue resistance, corrosion resistance and heat resistance within the specified use and storage period. Sheet metal processing parts are not only complex in shape, but also require the use of a variety of materials with high specific strength, heat resistance and corrosion resistance. Among various materials, the largest amount is hard aluminum, superhard aluminum and rust-proof aluminum alloy. Chromium-nickel-titanium stainless steel is used in rocket engines in large quantities. Titanium alloys not only have high specific strength, but also have good heat resistance and corrosion resistance. The proportion of materials used in sheet metal processing parts is increasing, and they are mainly used to make parts such as skins, partitions, and gas cylinders.

Hello! Welcome to EMAR's website!

English

English » »

» »

Spanish

Spanish Arabic

Arabic French

French Portuguese

Portuguese Belarusian

Belarusian Japanese

Japanese Russian

Russian Malay

Malay Icelandic

Icelandic Bulgarian

Bulgarian Azerbaijani

Azerbaijani Estonian

Estonian Irish

Irish Polish

Polish Persian

Persian Boolean

Boolean Danish

Danish German

German Filipino

Filipino Finnish

Finnish Korean

Korean Dutch

Dutch Galician

Galician Catalan

Catalan Czech

Czech Croatian

Croatian Latin

Latin Latvian

Latvian Romanian

Romanian Maltese

Maltese Macedonian

Macedonian Norwegian

Norwegian Swedish

Swedish Serbian

Serbian Slovak

Slovak Slovenian

Slovenian Swahili

Swahili Thai

Thai Turkish

Turkish Welsh

Welsh Urdu

Urdu Ukrainian

Ukrainian Greek

Greek Hungarian

Hungarian Italian

Italian Yiddish

Yiddish Indonesian

Indonesian Vietnamese

Vietnamese Haitian Creole

Haitian Creole Spanish Basque

Spanish Basque